2

2

Yes, we figured that out when Luke came with the Testo. 1/6 of a cord lasts us 7-10 days depending on weather. If we were burning oak or madrone only, it should be able to last 2 weeks or more. When I was a kid, we had a 100 year old wood stove that could easily consume 1/6 of a cord PER DAY!!! And even more on many occasions. Our wood box probably held 1/4 of a cord, and with less dense wood, it could go through that in a day, no problem, saying nothing of all the wet wood we burned because we would run out of wood in the middle of the winter and have to go cut more. I vowed I would never do that. Now I use so little wood that I never have to.Glenn Herbert wrote:If your wood rack is 4' x 4' with one layer of stove length wood, that would be 1/6th of a cord. Sounds much better for wood usage

Evolve.

Dirtling Farm https://www.youtube.com/channel/UCWN8bHd4A0uMW8kF_v4J7GA

1

1

Whoah!! Check out this permie deal!! https://permies.com/w/homesteading-bundle?f=232

"The only thing...more expensive than education is ignorance."~Ben Franklin. "We can easily forgive a child who is afraid of the dark; the real tragedy of life is when men are afraid of the light." ~ Plato

2

2

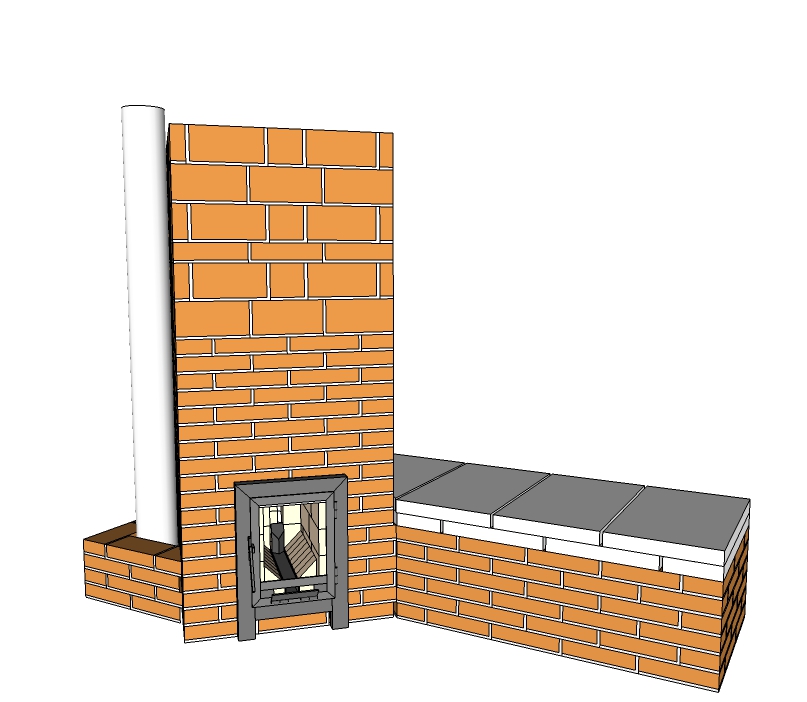

Carla Burke wrote:Solomon, this is GREAT!! Do you have any pics of the whole thing, at the current stage?

Evolve.

Dirtling Farm https://www.youtube.com/channel/UCWN8bHd4A0uMW8kF_v4J7GA

Whoah!! Check out this permie deal!! https://permies.com/w/homesteading-bundle?f=232

"The only thing...more expensive than education is ignorance."~Ben Franklin. "We can easily forgive a child who is afraid of the dark; the real tragedy of life is when men are afraid of the light." ~ Plato

2

2

Carla Burke wrote:Thank you - sounds like it's working out well, for you. I'm still exploring ideas, and am very happy to learn as much as possible about all the different types of rmh.

Evolve.

Dirtling Farm https://www.youtube.com/channel/UCWN8bHd4A0uMW8kF_v4J7GA

1

1

Evolve.

Dirtling Farm https://www.youtube.com/channel/UCWN8bHd4A0uMW8kF_v4J7GA

|

It is difficult to free fools from the chains they revere - Voltair

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|