3

3

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

4

4

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

1

1

I don't own the plants, they own me.

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

2

2

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

I don't own the plants, they own me.

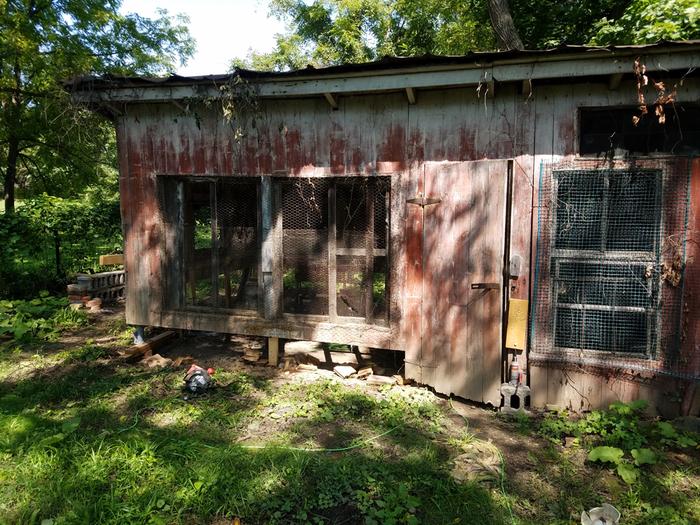

Matt Todd wrote:Man I continue to relate to you. I had a lean-to building (different from the previous mentioned) that had tongue and groove boards rotting into the dirt all around. Jacked it up, sawed them off, and replaced all around the base with treated 12x2's. Expensive but should last a damn long time and up my predator/rodent proofing.

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

1

1

I don't own the plants, they own me.

5

5

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

3

3

Glenn Herbert wrote:Nice work!

You might enjoy the Historical Timber Framing, Traditional Building and Architecture group on Facebook - members often have to repair centuries-old structures while keeping as much as possible of the original. There are lots of ideas for attaching new wood to old in structurally sound ways.

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

4

4

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

4

4

Year 4 of gardening. Orchard is happy, grass needs a goat. And the garden is about to get swallowed by surrounding trees.

1

1

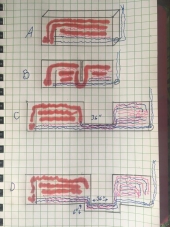

Please give me your thoughts on my Affordable, double-paned earthbag window concept

|

No, tomorrow we rule the world! With this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|