2

2

7

7

regards, Peter

6

6

2

2

3

3

regards, Peter

3

3

3

3

4

4

1

1

Eugene Howard wrote:To be clear, I wasn't talking about shipping cast cores. Only foam molds from which the end user could cast his own. But at this point in time, I would remain skeptical as to longevity of cast boxes or risers....at least till we find otherwise.

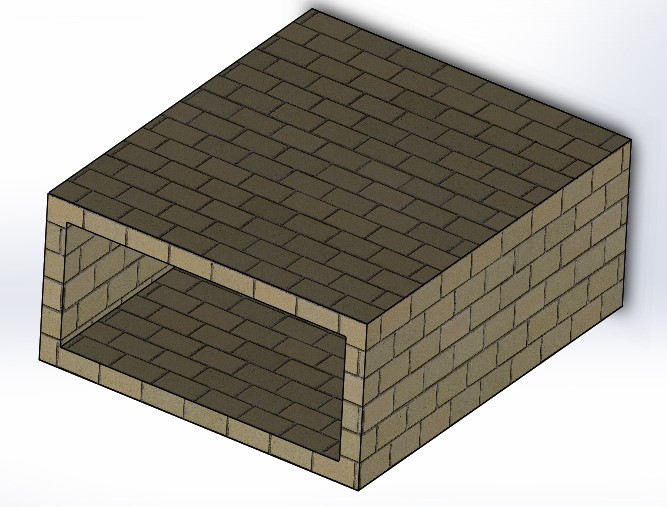

So if a large single bell was to be built into that wall, and fly ash is going to build up on floor of the bell over time, it seems like it would need one or more clean out access doors at base along the front. Perhaps even one on either side of the batch box?

What would work / be available for these clean outs, since what lies behind them would be still warm and active flue gases? Not when cleaning out, but when heater is in operation. Doors would have to be able to seal up 100%. Is there an off the shelf commercial option? Perhaps a round, cast iron pipe or drain fitting, with cast iron screw in plug? Those might go as large as 6 to 8 inches?

Also, to maximize front face radiant area, my first thought was to allow an offset in a back corner of the bell for a stove pipe riser. So giving that some more thought, also seems a clean out of some sort would be needed at the base of the stove pipe? But how to do that with it buried in the wall behind the bell?

Perhaps that can be accessed from one of the other front clean out doors?

![Filename: IMG_0567.jpg

Description: [Thumbnail for IMG_0567.jpg]](/t/208188/a/200249/IMG_0567.jpg)

1

1

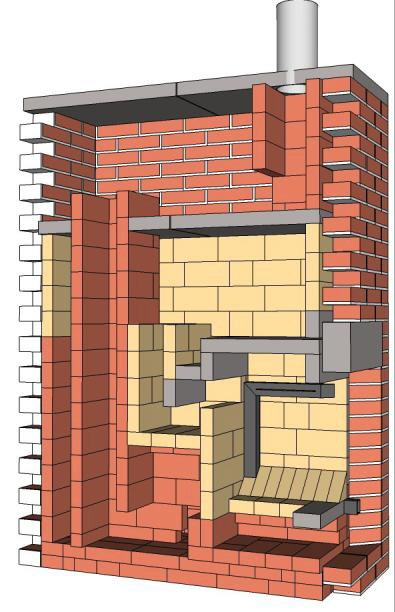

Eugene Howard wrote:The original idea / concept was to take the central part of the existing build, with wood burning, wood wasting heatilator type fireplace and wipe the central part clean. Everything in the photo below "Home". My original though was to replace it with a masonry heater. As I'm learning about the simplicity and effectiveness of a RMH combined with a single bell, that looks like the way to go.

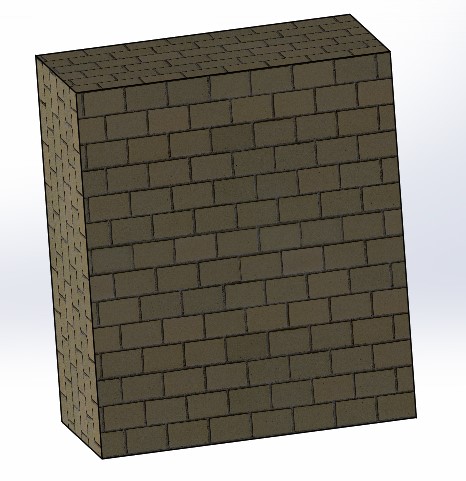

Dimensions are 30 inches deep......could be 36 inches..........and the front is 6 feet wide and from raised hearth to top of that segment, 7 feet. So opening to work with is 36"D x 72"W x 84"H.

The existing flue is contained in existing chase behind "Home". From there to chimney cap on roof is maybe 12 feet and all of existing flue is retained inside building envelop until it emerges at chimney top / cap.

| I agree. Here's the link: http://stoves2.com |