posted 2 years ago

Hi Ralph,

A couple of observations.

It appears that you're using internal rebar "pins" to resist some of the lateral forces the walls might be subjected to? Whether you need to pull a building permit or not, or had this structure engineered, there's a building code that covers this aspect of straw bale construction. See IRC Appendix AS Strawbale Construction, Section AS 105.4.2 Pins. You can download a free copy of this building code from the California Straw Building Association website, www.strawbuilding.org. Even if your state hasn't adopted this code and you're not required to pull a permit, it offers useful guidelines on building code-level straw bale structures.

Paragraph (3) of this code section covers internal pins, and specifies spacing (24" OC), laps (a full bale depth), and connection to both sill and the top plate/roof assembly. The commentary to this code states ..."the practice of internal pinning has fallen into disuse by most practitioners of straw bale construction due to its greater difficulty and cost compared with other means of achieving the same or better wall stability."

Even though it's considered archaic in N. America, plenty of straw bale buildings built prior to the early 2000s used rebar for internal pinning--it's just no longer common, due primarily to the difficulty of accurately impaling a 60 lb. to 85 lb. straw bale on the rebar so the bale surface stays in plane with those above and below it. There are a couple of work-arounds--pre-drilling a pilot hole using a hole saw with bit extension, or using vertical 2x guides to keep the bale aligned as you push it through the rebar. Note that internal pinning may not be sufficient by itself to resist lateral forces--you might need some other kind of bracing--if you haven't already planned on this.

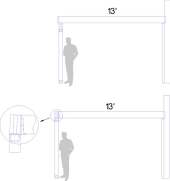

Also, most straw bales in N. America used in straw bale construction are either 2-string or 3-string. 3-string bales are reliably 15" tall, 23" wide, and between 46" and 52" long. There's greater variation among 2-string bales, but they are most often 16" tall, 18" wide, and between 40" and 46" long. The only dimension among these common bales sizes that fits on a 16" wide footing is a 2-string bale placed on-edge. I worked on one project in N. California where we used 2-string bales that were 16" tall x 16" wide, so bales could be placed either on-edge or laid-flat, but it's not a common bales size.

You might check out the California Straw Building Association's Straw Bale Building Details: An Illustrated Guide for Design and Construction, also available through the CASBA website or on-line retailers. It has been in print for around five years (since summer of 2019), and is still the most current book on straw bale design and construction as practiced in N. America. It references the straw bale construction code (available for adoption in U.S. code jurisdictions, and advisory elsewhere) throughout, and describes best practices for everything from insulating between sill plates to handling electrical and plumbing in straw bale walls, attaching partition walls and ledgers for cabinets, handling and stacking bales, plaster preparation, plastering, and more!

Jim

Many Hands Builders

8

8

8

8

4

4

2

2

1

1