2

2

Michael

Limón-Indanza, Ecuador

1

1

2

2

William Bronson wrote:I think removing a barrel from inside of a brick chimney would be a pain in the butt.

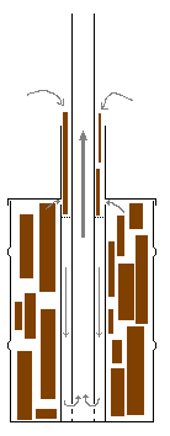

This design would be easier to unload:

https://www.google.com/amp/s/www.instructables.com/How-to-Make-some-Charcoal/%3famp_page=true

As built, they use cement board.

I am not sure how durable that proved to be.

Your bricks should be fine.

Something that is close to your initial idea is this :

https://youtu.be/NrTaISI9fm4?si=vf3I2S0aCyq87OjY

Michael

Limón-Indanza, Ecuador

1

1

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

3

3

John Suavecito wrote:I agree with William about how much extra work it would be to continually move bricks each time…

The retort is great if your priority is to be able to leave it and let it go out by itself. That isn't my priority. My problem was that it didn't make enough biochar for my needs in my garden.

Michael

Limón-Indanza, Ecuador

3

3

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

1

1

John Suavecito wrote:I hope you take pictures so others can try this design or develop their own version. I look forward to seeing it.

Michael

Limón-Indanza, Ecuador

|

They worship nothing. They say it's because nothing is worth fighting for. Like this tiny ad:

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|