Julian Adam wrote:My outer skin will be load-bearing so it's quite important the strength of the mortar is maintained.

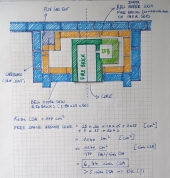

I understand you are building a double-skin heater with a batchrocket core inside. The outer skin will be fine when done with lime/sand/portland mortar. The inner skin is an entirely different story, it should be separated from the outer skin. Most people use 1/2 inch superwool between the skins, or cardboard that is pulled up every 5 layers or so. This separation is there to provide an expansion joint as well as a slip joint, the inner skin will get hotter and will expand as a consequence, mainly in vertical direction.

Now, the inner skin can be done in the same mortar and bricks as the outer one, *up to the height of the riser*. Above that level, you should switch to firebricks (on edge) and real refractory mortar. Care must be taken that the firebricks don't make any connection with the outer skin, otherwise the outer skin will crack, badly.

The top of the bell could be done with upside down steel T-profiles and firebricks between the steel. All faces of the steel should be separated from any bricks by means of 1/2" superwool or ceramic paper. When done properly, this construction will hold indefinitely.