Rocket Mass Heater Plans: Annex 6" L-shaped Bench by Ernie and Erica

will be released to subscribers in:

soon!

24

24

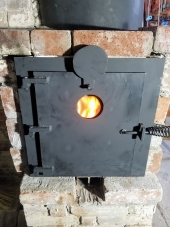

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

Shodo

Mountains and Waters Alliance

8

8

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

Shodo

Mountains and Waters Alliance

7

7

Silence is Golden

For all your RMH needs:

dragontechrmh.com

4

4

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

thomas rubino wrote:Hi Eugene;

The size of the fuel load itself is immaterial to the volume of heat output. (A batchbox does not have to be fully loaded each time)

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

7

7

Glenn Herbert wrote:A J-tube the same system size as a batch box will eventually heat up the same bell fully. How long it would take depends on the specifics of the situation.

regards, Peter

5

5

9

9

regards, Peter

5

5

6

6

Peter van den Berg wrote: in about 13 years, time and again the J-tube proved to be about half as powerful as the 1st gen. batchrocket for the same size

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

10

10

Glenn Herbert wrote:A J-tube with natural draft not needing the chimney warmed to burn well, I believe, could work fine in a larger bell while taking longer to store as much heat. The ISA of my bell is irrelevant to the early functioning, when any size bell would still be cold.

regards, Peter

7

7

Benjamin Dinkel wrote:And if the core isn’t within a bell the core surface counts as well. And a barrel obviously counts too.

regards, Peter

6

6

Peter van den Berg wrote:

But... there is a certain effect that is firmly based on physics, the kind that won't be influenced by faith. That effect is mostly referred to as "chimney stall". About +/- 20 minutes into the burn, the exhaust gases into the chimney need to be warmer than 60 ºC (140 ºF), otherwise the chimney draw will cease to exist and all smoke will stream into the house. What I mean with temperature measurement, is done in the very center of the chimney pipe, where the stream has its highest temperature and velocity.

5

5

Peter van den Berg wrote:

Glenn Herbert wrote:A J-tube with natural draft not needing the chimney warmed to burn well, I believe, could work fine in a larger bell while taking longer to store as much heat. The ISA of my bell is irrelevant to the early functioning, when any size bell would still be cold.

Forgive me Glenn, for not mentioning why the above statement won't hold, so here we go.

Of course you are entitled to believe whatever you like.

But... there is a certain effect that is firmly based on physics, the kind that won't be influenced by faith. That effect is mostly referred to as "chimney stall". About +/- 20 minutes into the burn, the exhaust gases into the chimney need to be warmer than 60 ºC (140 ºF), otherwise the chimney draw will cease to exist and all smoke will stream into the house. What I mean with temperature measurement, is done in the very center of the chimney pipe, where the stream has its highest temperature and velocity.

I stumbled upon this phenomenon many years ago and it took a lot of time to understand what the hell was happening. As you may know, combustion of woody material will produce heat (obviously), CO² and water vapor. Quite a lot of the latter, about half a liter of liquid water for every kilogram of bone dry fuel. Translated in imperial measuments: 30.5 qubic inches of water for every 2.2 lbs of dry fuel. As such, it is a by-product of the combustion process, much like natural gas. When the fuel wasn't as dry to begin with, this water content will be added to what is going into the chimney.

For now, we concentrate on the water vapor. This will be sent into the chimney and when the temperature is low enough, something between 40 and 50 ºC (104 and 122 ºF), the vapor will condensate on the chimney wall into liquid water and runs down. Lower in the chimney it's warmer, so the water evaporates again and is added to the vapor that's already there. So it rises into the chimney, but since the gasses are more saturated with water vapor now, it will condensate in an earlier state and lower in the chimney so it runs down again. This process will be repeated over and over again, consuming more and more heat, until there's no more heat to carry the vapor to the outdoors and the chimney will reach the state what we call "stall". No more draw, all smoke and water vapor is streaming into the house.

Sometimes, the stall can be deminish by itself and the draw seems to be restored. But in almost all cases, within minutes the chimney stall shows up again.

If you like to check the above explanation, extend your bell by 100%, start the thing up stone cold and watch what happens.

7

7

Austin Shackles : email anshackles"at"gmail.com.

5

5

8

8

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

Eugene Howard wrote:So a few observations and perhaps clarifications......

1. Hotter stack temps.......don't stall the engine with too much load?

2. Less stack height? Can recall issues when folks put rockets in basements and ran flues up 2 or 3 stories and they didn't work? So short stacks to chimney top vs tall? Then there would be issues with inside chimney stacks vs. outside?

3. Does it matter if chimney flue pipe is single or double wall?

Seems like there are a lot of engineering variables to consider.......and perhaps some guildelines set forth as something to consider and follow?

2

2

5

5

4

4

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

|

There's no place like 127.0.0.1. But I'll always remember this tiny ad:

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|