2

2

Do it.

Do it.

r john wrote:Jay

I am into commercial woodfuel production drying split logs in solar kilns for the domestic market and woodchip for power generation. The woodchip is converted into torrefied wood using hot thermal oil in a sealed kiln which produces woodgas which is fed into a gas fired (Jenbacher) generator the waste heat from the exhaust heating the thermal oil the electric generated being fed into the national grid.

Marcos Buenijo wrote:

r john wrote:Jay

I am into commercial woodfuel production drying split logs in solar kilns for the domestic market and woodchip for power generation. The woodchip is converted into torrefied wood using hot thermal oil in a sealed kiln which produces woodgas which is fed into a gas fired (Jenbacher) generator the waste heat from the exhaust heating the thermal oil the electric generated being fed into the national grid.

John, please clarify the configuration. Your second statement suggests that you are feeding pyrolysis gas directly into the Jenbacher, but this doesn't seem right. Rather, are you fueling a gasifier with the torrefied wood chips, using the producer gas from the gasifier to run the Jenbacher, harvesting the waste heat from the engine with thermal oil, then using the thermal oil to torrify wood chips, then sending the pyrolysis gas from the wood chips into the gasifier for processing?

r john wrote:The torrefication process is carried out in a retort which is heated by hot thermal oil. The gas given off whilst heating the woodchip to turn it into torrefied wood is fed into the jenbacher to produce electric the exhaust then heats the thermal oil. Nothing to do with FEMA type gasifiers

Marcos Buenijo wrote:

r john wrote:The torrefication process is carried out in a retort which is heated by hot thermal oil. The gas given off whilst heating the woodchip to turn it into torrefied wood is fed into the jenbacher to produce electric the exhaust then heats the thermal oil. Nothing to do with FEMA type gasifiers

I'm interested to understand the process. Heating wood in a retort with thermal oil will cause the wood to pyrolyse and release a gas very heavy in tar vapors. This is why I presumed there to be an additional gas processing step. I've never heard of a reliable engine system fueled by pyrolysis gas, so naturally I am excited about the prospect.

- What components lie between the retort and engine?

r john wrote:I believe its a fluidized bed steam reactor from what I understand it contains a methane membrane. Its just standard kit on a Jenbacher woodgas engine. I dont think the slow pyrolysis produces the same tar problems that you get in a conventional low temperature gasifier. The majority of the gas produced in torrification is steam reducing the moisture content from 45% to 3 %.

Marcos Buenijo wrote:

r john wrote:I believe its a fluidized bed steam reactor from what I understand it contains a methane membrane. Its just standard kit on a Jenbacher woodgas engine. I dont think the slow pyrolysis produces the same tar problems that you get in a conventional low temperature gasifier. The majority of the gas produced in torrification is steam reducing the moisture content from 45% to 3 %.

Thanks for the replies. If this is a commercially available gasifier, then let me know of a web site that might be available where the system is described. There must be some sophisticated gas processing components in the system. I'm curious to check it out.

Do it.

r john wrote:Just type in Jenbacher woodgas filter. The engines are not small but they do know what there doing if your seriously into gasification.

2

2

A few years ago I developed a gasifier forge. It operates on demand, I feed it with Virginia pine (useless otherwise) - it loves a good sappy knot. Some chunks are on the sides, the 1" pieces for operation, smaller stuff to start up. 3-4" length works good since the throat/burner is a scrounged piece of 3" stainless exhaust tubing. No idea of 'yield' but I was heating spikes to a bright orange. The fuel scoop is made of one.Jay Peters wrote:Hello home-brew gas enthusiasts!!

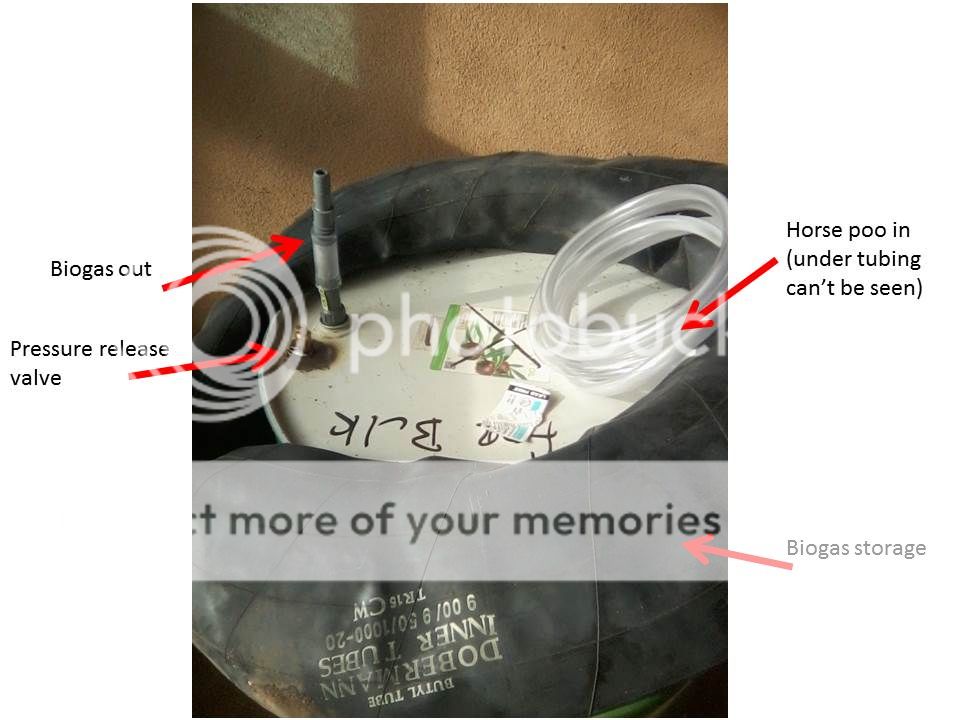

The intention of this thread is to gather first hand accounts of anyone who is or has made and used home made gas on a home scale. Are you using gas somehow? Tell us! Whether its a digester feeding a stove top or a woodgas driven truck or genset.. if it is or was in use I'd like to hear all about it...pictures are also nice!

Perhaps this thread already exists somewhere in the bowels of this forum, if not let this be it! If so, tell me to shut up and I'll dig harder to find it!

I'm interested in all of it:

How are you producing producing : digester or a gasifier or by some other means i'm not aware. If so, what kind?

If you are operating on demand (if gasifying) or storing. how?

What sorts of feedstock are you using?

What are your yields?

How are you using the gas?

Pros and Cons of your systems? What are the day to day challenges? If you were to do it again, what would you do differently?

I've spent a lot of time reading excellent posts by Marcos Buenijo, Bill Bianchi, Abe Connally and others on this forum with great interest. Following the links, checking out videos and reading the papers.

To reiterate what I'm interested in here is getting first hand accounts of Home scale gas producing and burning systems of all types and the realities of constructing, maintaining and using such systems.

Thank you!

j

Do it.

Jay Peters wrote:Very Cool, Bob and Nice pics too! Any more detail you can hook us up with on the design? On demand definitely seems like a wise choice in terms of wood gas. It seems that storage by any means other than the original biomass feedstock is pretty problematic. All in all this is a very cool solution to propane and natural gas forges!

Ed - I've poured over the All Power Labs GEK website, brochures, videos, and CAD files extensively. Very interesting innovation being done there.

I personally would like to get a small wood gasifier and generator set-up going in the future to charge batteries when the sun isn't shining or to run when more energy intense demands require. I'm also interested in generating enough methane to run a gas cook stove using jean pain style digester. I've found lots of info to research but not much of it includes personal experience with these types of small systems. It seems clear to me that the wood gas generator is certainly possible and the tech is pretty clear...what I haven't found is personal experiences with such a system and the realities of putting one together. The jean pain digester is however more nebulus as far as I can tell as there seems to be some disagreement on actual yield and process.

Any more takers?

j

1

1

--

David William House

"The Complete Biogas Handbook" www.completebiogas.com

Vahid Biogas, alternative energy consulting www.vahidbiogas.com

[Beginners Biogas Workshops! http://completebiogas.com/workshops.html]

"Make no search for water. But find thirst,

And water from the very ground will burst."

(Rumi, a Persian mystic poet)

www.bahai.us

| I agree. Here's the link: http://stoves2.com |