I agree that many commercially sold low fire pottery wares are something to be cautions of...with most being downright unsafe!

yeah making art is sketchy, the glazes and the chemicals and doing all sorts of unsafe stuff!

perhaps its a good thing most artists are at least a little bit crazy =P

the worst part of this potential toxic element of pottery is with the weird glazes people use. without using toxic glazes thats a different thing.

but theres better glazes without much weirdness, and if you get them to the right temperature will seal off the clay and then make it not pourous.

sometimes you see a lot of bowls that are raw on the outside, and just glazed with a simple glaze on the inside, i like that style. thats up to standards of "food safe" pottery, while still having the raw and simple look. using the non toxic glazes available and being careful to get it to its maximum temperature.

i am inclined to think that with the right clay and a capable person knowing what they are doing this raw unglazed clay MIGHT be ok food use...but they would have to be very precise about getting to the exact right temperature with their specific clay.

like i said i am not really good at being the voice of reason, i'm much more crazy ideas girl, and count on the more grounded people around me =)

but perhaps the ideas about "food safe" pottery are erring too much on the side of overly cautious.

so here i will borrow some voices from internetsland.....some relevant notes....actually this is linked up to the link on the last page, some very interesting reading and artists pages there...

http://www.potters.org/subject92923.htm

"I suppose you could use some kind of plastic sealer, but not in order to use

the piece as functional ware. Pit-fired and bonfired wares are not for

food-service use. In the cultures where they use unglazed pottery, the

children grow up with resistance to the bacteria that grow in the clay. If

you or me prepared and ate food out of unglazed pitfired wares, we'd likely

experience intense gastrointestinal distress. Best to just accept that

pitfired and bonfired wares are decorative and non-functional, and make

glazed wares to drink your coffee. "

"Because the pit fire is low fire the pieces are not food safe but

enjoyed for their beauty."

"I wouldn't have coffee out of any pot! ptooy. Now if you had asked

would I try Dr Pepper out of a pit fired pot I would have said, "No,

it a waste of perfectly good Dr Pepper." The only function of pit

fired pots fired here in NA is the function of looking really cool.

The bodies I use in the pit are nowhere near fused enough to contain

water without leaking. Also, when I've fired pots with copper

sulfate, copper carbonate, miracle grow, etc. I don't want to lick the

pots afterwards no matter how yummy they look."

"Please do not

take offense, Earl, but I think that trying to seal a pitfired piece to make

it hygenic is a ridiculous idea. "Modern times" has nothing to do with it.

There are appropriate methods for making utilitarian pottery, and pit firing

certainly is not one of them. Everything about the pit firing process makes

it inappropriate for functional pots. "

"> Maybe I'm missing something here, but isn't pit firing exactly how we got

> our first functional wares in history? I'm not trying to be a smartass or

> anything, but surely I'm missing something here."

Philip -

Well, no, they were bonfired rather than pitfired. And as I clearly

explained in a previous Clayart post, in our culture we do not have

resistance to the bacteria that grow in porous clay, and thus would

experience severe intestinal distress if attacked by those bacteria. You

have to grow up from birth with those bacteria in order to develop such

resistance, and in those cultures, the resistance may even be inherited.

The idea of sealing pitfired wares in order to use them as utilitarian pots

seems incredibly impractical and inappropriate. I am surprised that anyone

would even consider it."

Bonnie Staffel on thu 6 apr 06

Back in my early days of making pottery, there was a sealing remedy for

teapots where the glaze had crazed.. The premise was that the tea

itself

would seal the pores, and that one never washed a teapot in soapy water,

but

let the tannin (?) build up inside the pot. Another remedy that was

widely

used was to soak the pot in milk. I did not like the latter remedy as

then

you got the "pantry" odor to your dishes from the soured milk residue in

the

pores. It might be interesting to test using strong tea as a sealant.

However, there might be a stain left from the tea.

Nori wrote:

"I'm selling some saggar pit-fired pots for the first time, and i want to

make a card for each pot, on care & use. But every time I write the

contents, it's full of don'ts, can'ts & not's. Pretty negative. Can anyone

suggest some positive wording for this?"

"

Nori -

I am not sure that you can complete eliminate the negative warnings, because

they are necessary. I think that the best explanation statements in such

situations start out by emphasizing the positive qualities of the work. I

would include a brief explanation of the process and then a statement

pointing out the nature of celebratory ritual in the bonfire, pit, or sagger

firing, and the importance of the finished ware as the record of that

process.

I have a statement like that in my "Intro to Clay" syllabus in

reference to the blackware bonfiring that we do. My statement goes like

this: "The bonfiring process has the quality of celebratory ritual, and the

wares have an evocative beauty that speaks of the firing process, but

bonfired wares are more fragile and porous than those fired in other

processes, and cannot be used to contain food or liquids."

"

Vince wrote:

<usage throughout the world, and contemporary pottery usage in many tribal and

Third-World cultures. But it is important to point out that there are

significant health concerns to be considered here. In cultures which use

unglazed, porous pottery for daily cooking and eating, children grow up

exposed to the bacteria which live in the porous clay, and develop strong

immunities.>>

I think the last sentence should read, "children that survive grow up ..."

Otherwise I agree with Vince's point. The user that a studio potter faces in

the US is uneducated in the use and appreciation of highfired, non-Walmart

ceramics. These same people are Wildly uneducated about the use of pitfired

ceramics as functional vessels. To call a pot functional assumes the

potential user understands what that functionality is. For example, if a user

expects a pot to survive stovetop use, exposed to flame, then no stoneware

object is functional. The question of functionality assumes that the maker

and the user have an understanding of the limits of meaning of that word"

"

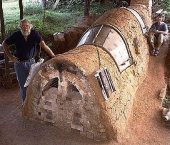

History

A pit firing is one of the most universal, primitive firings executed today. Firings of this type were an adaptation to firing the ware in bon fires. At some point it was discovered that digging a pit in the ground and firing the ware in a pit led to higher temperatures resulting in a more hard, enduring fired clay. As time continued pit firing evolved to digging holes in the mountainside, a primitive version of today's Anagama. "

from:

http://www.claystation.com/technical/firing/pit_techniques/intro.html

2

2

3

3

4

4

1

1

1

1

1

1

1

1

1

1

) but I've been wondering about firing.

) but I've been wondering about firing.

1

1

3

3