2

2

positively optimistic 🙂 https://www.youtube.com/@613Builds

![Filename: image.jpeg

Description: Rusty drum barrel and supporting plate are only to show a preview of the cast core rocket idea [Thumbnail for image.jpeg]](/t/53224/a/36776/thumb-image.jpeg)

positively optimistic 🙂 https://www.youtube.com/@613Builds

2

2

![Filename: IMG_0543-w600.jpg

Description: 6" core cast w/ refractory cement/perlite in galv box [Thumbnail for IMG_0543-w600.jpg]](/t/53224/a/36795/IMG_0543-w600.jpg)

![Filename: IMG_0536-w600.jpg

Description: demo assembly w/ half-barrel bell & 35 gal drum over riser [Thumbnail for IMG_0536-w600.jpg]](/t/53224/a/36796/IMG_0536-w600.jpg)

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

lol jk

lol jkpositively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

![Filename: image.jpeg

Description: Mason mortar and fireplace mortar and refractory cement. Similar ingredients as I used in my first rocket [Thumbnail for image.jpeg]](/t/53224/a/36927/thumb-image.jpeg)

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

but I wasn't sure about the legs. I'm too cheap to buy the barrel stove kit(s). I could make legs or stands but who knows how ugly that would be

but I wasn't sure about the legs. I'm too cheap to buy the barrel stove kit(s). I could make legs or stands but who knows how ugly that would be

positively optimistic 🙂 https://www.youtube.com/@613Builds

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote: use a 50 gal bell and sink the manifold down inside beside the core instead of out the side of the bell and you will see the performance increase.

positively optimistic 🙂 https://www.youtube.com/@613Builds

Any ideas to make this easier with basic tools and a dirt floor work shop? If I had my way, I'd use a laser level to mark the optimal line, but I don't have one of those, or the level floor either lol

Any ideas to make this easier with basic tools and a dirt floor work shop? If I had my way, I'd use a laser level to mark the optimal line, but I don't have one of those, or the level floor either lolpositively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

![Filename: image.jpeg

Description: Interesting stuff I saw yesterday [Thumbnail for image.jpeg]](/t/53224/a/36979/image.jpeg)

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

positively optimistic 🙂 https://www.youtube.com/@613Builds

Glenn Herbert wrote:That looks fairly similar, probably a bit larger than the 6" J-tube core I cast in an old galvanized steel box.

The riser is 10" OD, 6" ID, with 2" perlite-clay fill. It worked great, and the whole assembly drafted well on a 90 F day at an Earth Day demo, with the exhaust cool enough to just about hold a hand in it. We dismantled it after 2-3 hours burning, and the box was too hot to touch with bare hands, but after a half hour or so of cooling we could load it into a car.

![Filename: image.jpeg

Description: Top view, the 14" drum diameter is the diameter of my entire mass on my other stove, this core holds more [Thumbnail for image.jpeg]](/t/53224/a/37028/thumb-image.jpeg)

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

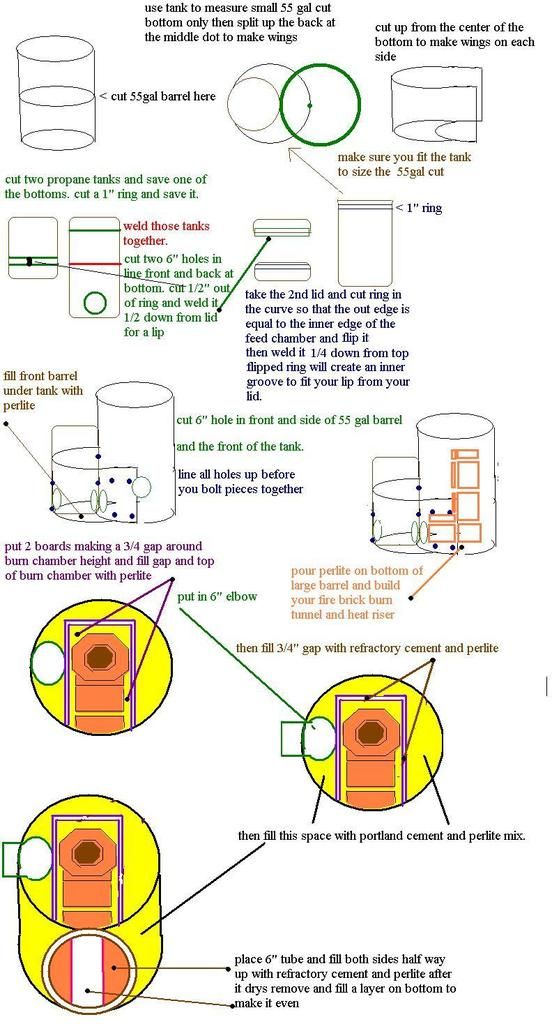

John McDoodle wrote:Who is good at math? I want to figure out how many liters by volume my "tub" core mould will hold? Then I can figure out 60-70% of that is how much perlite I need, in liters, which is how the perlite is measured and bought, by the liter , by volume.

My core is 16" x 32" x 20"

That's 10,240 cubic inches?

My burn chamber is 20" x 6" x 6" = 720 cubic inches

My feed chamber is 6x6x9" = 324 cubic inches

My riser is (Pi) 3.14 x (Radius) 6" x (length) 14"= 263.76 cubic inches?

My core mix volume does not include the feed or burn chamber or riser, so I will subtract them from the total tub volume 720+324+263.7= 1307.7

How many liters fits into 10240 -1307.7 = 8932.3 cubic inches?

I feel confident that my math is good, EXCEPT for the riser, I'm sure that my math there is wrong.

Any input or help from any math whiz? I'm trying to figure out how many liters of perlite makes 65% of my core volume...

positively optimistic 🙂 https://www.youtube.com/@613Builds

F Styles wrote:are you mixing perlite into the refractory cement for your actual burn core tunnel and heat riser?

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:

F Styles wrote:are you mixing perlite into the refractory cement for your actual burn core tunnel and heat riser?

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

positively optimistic 🙂 https://www.youtube.com/@613Builds

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

|

Sure, he can talk to fish, but don't ask him what they say. You're better off reading a tiny ad:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|