1

1

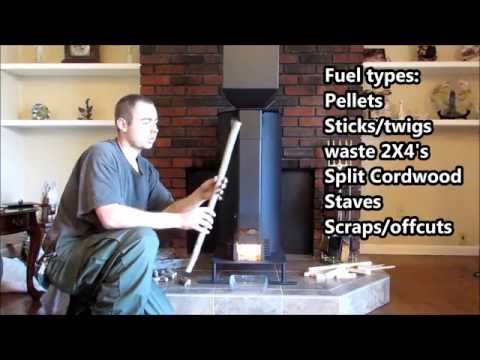

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

Creator of Shire Silver, a precious metals based currency. I work on a permaculture farm. Old nerd. Father.

5

5

Moderator, Treatment Free Beekeepers group on Facebook.

https://www.facebook.com/groups/treatmentfreebeekeepers/

5

5

2

2

1

1

positively optimistic 🙂 https://www.youtube.com/@613Builds

I have been working on a heater that uses 2 55 gallon drums stacked that looks like one of those conventional stacked drum woodstoves. My design if successful will use the second drum as the heat sink. I want the RMH to be effective in heating situations that won't allow a large heat sink. It will be moveable since both drums have removeable lids. It is quite heavy when assembled but can be disassembled down to bare 55 gallon drums.

I have been working on a heater that uses 2 55 gallon drums stacked that looks like one of those conventional stacked drum woodstoves. My design if successful will use the second drum as the heat sink. I want the RMH to be effective in heating situations that won't allow a large heat sink. It will be moveable since both drums have removeable lids. It is quite heavy when assembled but can be disassembled down to bare 55 gallon drums. "When there is no life in the soil it is just dirt."

"MagicDave"

1

1

Robert Fairchild wrote:330 Stainless is about as good as it reasonably gets. Rated to 2100F. It's what InStove uses for their grates. I bought 26 3x8 sheets for $75 each off Craigslist. Retail is over $300 a sheet. I'm using it for rocket stove liners, inside insulating firebrick, for rocket stoves for schools in Haiti.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

2

2

Humanity Learns.

2

2

Ronald Cline wrote:Research basalt, it is an abundant natural materials from volcanos. It is used today for many heat and strength purposes. I believe it maybe relatively inexpensive compared to your other metallic material listed.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

Humanity Learns.

Ronald Cline wrote:Do you know how much surface area of your design will exceed this temperature?

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Humanity Learns.

2

2

Ronald Cline wrote:I don't know, but I wonder if you use compressed dry clay powder instead of pre-fired brick, would it work. Mixing perlite with it may even boost its performance.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

Humanity Learns.

1

1

Chris

www.ecodiy.org

1

1

Chris Southall wrote:Why not use cast iron or even boiler plate - good enough for wood stoves and cooking ranges for centuries past. I used recycled heavy steel tube for my rocket stove and I am confident it will last many years

How permies.com works

What is a Mother Tree ?

Chris Southall wrote:Why not use cast iron or even boiler plate - good enough for wood stoves and cooking ranges for centuries past. I used recycled heavy steel tube for my rocket stove and I am confident it will last many years

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Tyrr Vangeel wrote:I was going to shout "asbestos!!", but then I looked it up what these geopolymers are.

They are not asbestos

But it appears to me that you are seriously upcycling some waste materials if this works.

Highly interested also in the 'burn everything' RMH!

Our petrol fired floor heating went 3 years ago, the wood stove is still keeping us warmisch, but some replacement would be great. Cord wood in abundance, but as my parents are agging and I'm considering leaving the house, they started considering the day they'll no longer be able to easily navigate stairs with wood in their arms and the floors are not strong enough to just build a RMH on top except for the cellar floor (where the broken petrol stove still sits).

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Bruce Woodford wrote:Sky, I believe your current design incorporates cooling fins to help deal with the heat issue in a steel core. Why not pursue that concept and go for an air-cooled core like the Steel RMH I am currently using which is up and running for this cooling season. See pics on my recent posts. Simplicity rather than complexity is often the solution!

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

1

1

Tom Robertson wrote:It's not the high Temps per se.

It's that at higher Temps oxygen is pulled out of the liner.

That's why metal liners burn out.

A liner needs to be non reactive to oxygen stripping.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Tom Robertson wrote:I'm going off what I've read.

What's your take on metal disintegration in the riiser?

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Sky Huddleston wrote:The science says that so long as the metal does not reach or exceed the point of incandescence the metal will last just as long in the form of a rocket heater as it would if it were made into a chair or table or whatever.

How permies.com works

What is a Mother Tree ?

Living in Anjou , France,

For the many not for the few

http://www.permies.com/t/80/31583/projects/Permie-Pennies-France#330873

Sky Huddleston wrote:

What it really comes down to is, a liner needs to be non reactive and resistant to bonding with oxygen at higher temperatures.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Living in Anjou , France,

For the many not for the few

http://www.permies.com/t/80/31583/projects/Permie-Pennies-France#330873

1

1

but then they are more difficult to sell and make money on

but then they are more difficult to sell and make money on

Living in Anjou , France,

For the many not for the few

http://www.permies.com/t/80/31583/projects/Permie-Pennies-France#330873

Burra Maluca wrote:

Sky Huddleston wrote:The science says that so long as the metal does not reach or exceed the point of incandescence the metal will last just as long in the form of a rocket heater as it would if it were made into a chair or table or whatever.

Well made chairs don't generally glow when you use them though, unlike the metal in business end of a rocket heater.

David Livingston wrote:Ok take a chair made of copper for example and leave it out side ; It will turn greenish but apart from that nothing much

Take a piece of copper place it in a flame about 400c like a bunsen burner well below any incandescent stuff and watch it turn black oxidise and eventually turn to powder . Reaction rates are dependant on temperature . lots of stuff can happen before things go incandescent. I think it a mistake to be concerned only with that part of the situation

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

Gordon Haverland wrote:I would be interested to find out where this idea about pulling oxygen out of the metal comes from. To me it is vaguely like the idea that "when steel crystallizes, it breaks".

Incandescence should only be a function of temperature. Many metals melt long before incandescence comes into play.

Lots of knowledge of high temperature metal usage comes from gas turbine knowledge. Cooling of hot parts is something that is done, as is the coating of parts with glass and/or ceramic. It is common to see yttrium oxide in these coatings. You would be unlikely to see any alkali metal oxide in such a coating (too high a vapour pressure). Some other metals that could be considered based on the temperature are rhenium, tungsten and alloys of tungsten with rhenium.

Some high temperature coatings do not revolve around glass/ceramic. One that comes to mind, is iridium (a platinum group metal).

I haven't done it myself, but seen in written a few times. It is possible to get aluminum to the point where the oxide skin is holding the object together. All the aluminum metal inside the skin has become liquid. Pierce the oxide skin, and the metal comes out and the object fails.

In terms of intermetallic compounds, it may be that nickel, iron or titanium aluminide could be considered. They all probably need an oxide (glass, ceramic) coating.

On the basis of temperature alone, carbon/carbon would work. There is far too much oxygen in your environment for carbon/carbon to last. It would need a coating. At some point, you will have built up full density through the fibre region, and then you would more or less switch to producing a layer for surface properties. You may be able to get a carbon based coating that is similar to an aerogel, or you might go for a carbon filled with particulate oxide. With particulate oxide, you may then be able to coat the material with an oxide (glass, ceramic) similar to a metal.

Thermal fatigue can be an issue with all these coatings, as you are going through a rather large change in temperature between stove not running, and stove running.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

I have nothing really to add to this, good stuff. All I have to say is that the incandescence often times correlates with accelerated oxidation, particularly in steel, stainless steel, nickel, copper, and other common metals. Much like how CO output correlates with grams per hour of fine particles even though they are different. Oxide coatings are usually expensive.

|

Blood pressure normal? What do I change to get "magnificent"? Maybe this tiny ad?

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|