Gordon Haverland wrote:

I have nothing really to add to this, good stuff. All I have to say is that the incandescence often times correlates with accelerated oxidation, particularly in steel, stainless steel, nickel, copper, and other common metals. Much like how CO output correlates with grams per hour of fine particles even though they are different. Oxide coatings are usually expensive.

Materials science is my field.

If Fe/Ni/Cu surfaces give rise to light emission at elevated temperature in an oxygen environment, you might think of it as combustion. Maybe. Different metals will have different emission curves as a function of temperature, but nominally yellow heat for steel should be the same for cast iron, nickel, stainless, copper, tungsten, tantalum, rhenium, iridium, ....

Some kind of surface chemistry on the fine particles? There is a chemical equilibrium between CO, CO2 and C.

The coatings are cheaper than making the bulk material out of a resistant material.

But that is sort of why I brought up the aluminides. Unlike aluminum metal, the part stays solid. Like aluminum, the surface is protected in large part by alumina. It can help to add other things to this alumina layer. Ductility has been a historical problem, but if you are comparing them to refractories they are probably okay. I suspect your cheapest one is going to be iron aluminide, and it probably has the worse properties of the 3. But, it has been a while since I read much about it.

Cold spraying might form a useful coating, but I think the various hot spraying methods might be better for you.

I do think your limiting factors are thermal fatigue of the coating (leading to spalling) and sulfur (selenium, tellurium).

I didn't know much about your stoves, and just read a bit at Wikipedia (before my first reply).

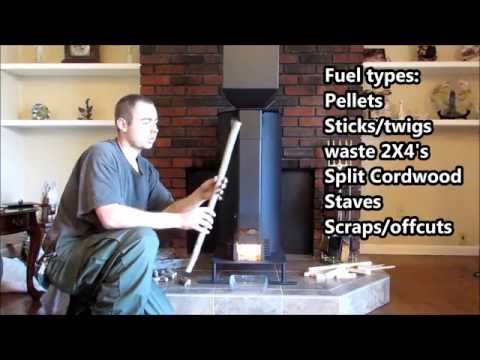

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

1

1

Gordon Haverland wrote:Austenitic stainless (300 series) is nominally a lousy conductor of heat. Can be good or bad.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

Jan Corriveau wrote:

Hello Gordon,

GeoPolymers are not a plastic at all. It was discovered and developed over the last 30 years by the GeoPolymer Institute in France. In the 70's, they had a bad wave of city fires and were looking for a material that wouldn't burn and release toxic fumes. The name GeoPolymers was coined because the scientist that discovered the process was a plastic polymer researcher and realized that you could apply polymerization to rock minerals in the same way as applied with plastic polymers but by using alkalies to soften up the rock bonds. Over the last 30 years, they discovered many applications and different ways to use it. This technology can be applied to so many fields that it would be hard to cover it all in a single post. GeoPolymers is a mean of making rocks at room temperature. Depending on ratios of minerals (Aluminas and Silicas), you get very different properties. Some mixes can be quite liquid before hardening or have a harder consistency than fresh uncured concrete on the other end of the spectrum. With the more

liquid mixes, it looks like and acts like an epoxy, except that it hardens as a rock once cured (curing is crazy fast). They used it like epoxy, with fiberglass to make statues and the like. They also experimented in making sealant. Imagine using a sealant that doesn't ever degrade to UV like the silicon sealant we use and is as hard as a rock. They also used it as a coating on metals which would be similar in some ways as a ceramic coating on a ceramic cooking pot once it's cured but all of that is done at room temperature. Some recipes may require heat, but the heat needed is nothing crazy. The more the silica to alumina ratio, the more heat resistance you have, which is what the Op wants. The range the Ops would want to look into are 20:1 up to 35:1 silicates to aluminates. They even looked into using casted GeoPolymers panels as a liner on foundries. At those ratios, it's almost like having pure sand that can be casted/sprayed, so the heat resistance would be VERY high. If you're curious to know more, this short pdf I linked goes over the last 30 years of research and the different fields they applied the technology:

https://www.geopolymer.org/fichiers_pdf/30YearsGEOP.pdf

The possibilities are pretty much limitless. I've come across one article that talked about GeoPolymers on permies to use in rocket mass heaters while looking to find recipes and others, but the info was minimal and I can't recall if it was more AAM (Alkalies Activated Materials) or a true GeoPolymer. Some people confuses both of them as the same and that has led to a bad rap for the product. The confusion was spread by the concrete industry and I would believe that it's possibly because the product can be used to replace concrete. Imagine if you can cast a granite block (amorphous and not crystalline like granite is normally found) for your house foundation, you'll never have cracks and will last 1000's of years easily. Also, because the molecular formation is a rock polymer, it's completely waterproof. So can be used for water tanks, under water, completely inert to alkalis, acids and salt water. At some point in his career, the scientist was asked to study the pyramids in Egypt and due to his knowledge of Geopolymers, he was able to recreate the blocks they made when building the pyramids and proved very easily that the pyramid are casted blocks at room temperature. He gives the recipe that they used if someone searches for it. The bottom first row of the pyramid was casted using some kind of burlap shapes and exhibits oozing at the bottom of the forms (which proves they were casted). The subsequent layers are casted in wooden forms, which explain their precision. Anyway, the material can be used for so many things. It's perfect for all of us that wants to have more freedom and less dependencies on stuff that breaks and needs constant repair but will require a bit of fiddling around.

I hope this helps clarify a bit what GeoPolymers are.

Cheers

Jan

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Burra Maluca wrote:

Chris Southall wrote:Why not use cast iron or even boiler plate - good enough for wood stoves and cooking ranges for centuries past. I used recycled heavy steel tube for my rocket stove and I am confident it will last many years

A properly functioning rocket stove will reach temperatures that will burn out cast iron and steel. This has been demonstrated over and over ad nauseam

Permies.com does not recommend the use of metal in the burn tunnel or heat riser of a rocket stove or mass heater. Please check out this thread - using metal in the burn tunnel and heat riser

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

Glenn Herbert wrote:I expect any of these super-high-temp elements or alloys would be so expensive that the quantities needed would be prohibitive for the ordinary builder.

There is also the factor mentioned numerous times that it is not just melting temperature, but corrosion resistance at high temperatures, that limits many materials.

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:

Glenn Herbert wrote:I expect any of these super-high-temp elements or alloys would be so expensive that the quantities needed would be prohibitive for the ordinary builder.

There is also the factor mentioned numerous times that it is not just melting temperature, but corrosion resistance at high temperatures, that limits many materials.

Glenn, I respect your opinion but Its seems as though you may not have clicked any of the links before you commented. The manufacturer of these materials rate these tubes for high heat furnaces and Nuclear applications. You cant get any harsher than Nuclear and rocket fuel environments.

as for price many of the manufacturers i listed sell in bulk and depending on what Sky orders may get him a break and is up to him what he wants to pay or what he finds affordable. As I said i found many places where to look and shop around for the best price for what Sky deems he needs.

From the site: Application:

Tungsten tube is widely used in the thermocouple protection tube, sapphire crystal furnace and high temperature furnace, etc. Tungsten is usually sintered processed and with 8mm wall thickness. Tungsten tube contributes stability to the hot zone. While high in thermal inertia, tungsten tube may prolong the growth cycle of the sapphire.

Nuclear aerospace and military industry (carrying boat,radiation shield,tungsten crucible for renewable nuclear fuel,rocket nozzle,throat,penetrator).

10,Vacuum or gas protected high temperature furnace material (sintering furnace,monocrystalline furnace,annealing furnace)

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:Its not just the heat that Glenn and many others are saying will destroy steel. the moisture of any kind with o2 can get into the pours of the 330 steel and expand it 1500 times and it can eventually weaken it.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:Yes many people here have reviewed 330 SS alloy and it is recommended not to exceed 1900 F. The better question may be are you going down the 330 SS alloy path so you can insulate the heat riser and if so, how can you guarantee the stove stops at the 1900 F suggested weakening point? If you decide to insulate your heat riser, it will turn your great stove craftsmanship into a dragon beast that may not have a guaranteed tame-able temperature limit. With many different types of wood burning at different temperatures no one type of design can guarantee a certain temp all the time from all woods and stages of dryness. It was also suggested Inconel for higher than 1900 F temps and you can find some links here of some suppliers and prices.

http://pacificalloys.com/Inconel.html

http://www.reliantpipes.com/inconel-incoloy-pipetubes-tubing/index.html

http://www.steeltubes.co.in/inconel-alloy-600-625-pipes-tubes-supplier-exporter/

source: https://www.marlinwire.com/blog/what-is-the-temperature-range-for-304-stainless-steel-vs-316-vs-330

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

F Styles wrote:Have you thought about testing the idea of stacking in ceramic rings (to avoid temp fluctuation cracks) that have ribs on the outside to put air space on the inside of a metal tube for burn chamber and heat riser and ship with removable Styrofoam inserts to avoid shipping breaks, that way you can insulate around the metal and keep it from breaking down the heat and also use cheaper metals?

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:am i correct in saying that you want a fix for the builds you have now and a 330 SS thin sleeve insert would help mitigate a potential problem until your next build?

i think you are correct in saying the burn tube is important also and i was actually thinking of using the ceramic rings in the burn tube as well and think it would creat more of a market for you as replacement parts or upgrades.

you could sell outer insulation sleeves and inner ceramic ring upgrades for currant units if its possible?

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

F Styles wrote:you can tell us here. We promise we wont tell anyone. just post it here on this thread and it will be safe.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

|

Yeah, but is it art? What do you think tiny ad?

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|