Scott H. Please take a look at the comments I made to John Littles thread

First Rocket Build - very pleased in the Rocket Mass Heater Forum Threads

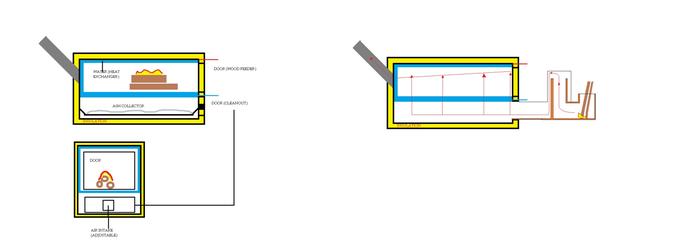

Building from the sketch you show, you will have Similar potentially dangerous consequences!

here is the Link :

https://permies.com/t/41349/rocket-stoves/Rocket-Heater-Build-pleased

I would also plan on making the Transitional area bigger with a larger opening into the start of the Horizontal piping of the Thermal mass, gradually tapering down to that size

pipe

This is a common trouble area and bigger , even 3 times bigger is better, this area is shaped free hand and can use scraps of chicken wire or hardware cloth to get the curves

needed for this space !

Hope you find this timely and helpful ! For the Good of the Crafts Big AL