4

4

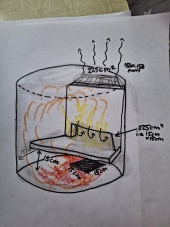

![Filename: IMG_0924-w600.jpg

Description: wood-fired kiln under construction [Thumbnail for IMG_0924-w600.jpg]](/t/57962/a/42205/IMG_0924-w600.jpg)

![Filename: IMG_0930-w600.jpg

Description: firebox nearly finished (16"w x 16"h x 60"l total) [Thumbnail for IMG_0930-w600.jpg]](/t/57962/a/42206/IMG_0930-w600.jpg)

![Filename: IMG_0925-w600.jpg

Description: ware chamber (30"diam x 30"h) - firebox extends under [Thumbnail for IMG_0925-w600.jpg]](/t/57962/a/42207/IMG_0925-w600.jpg)

![Filename: IMG_0986-w600.jpg

Description: start of first firing [Thumbnail for IMG_0986-w600.jpg]](/t/57962/a/42208/IMG_0986-w600.jpg)

![Filename: IMG_1001-w600.jpg

Description: some results. cone 06 (1800+ F) [Thumbnail for IMG_1001-w600.jpg]](/t/57962/a/42209/IMG_1001-w600.jpg)

2

2

![Filename: IMG_1193-w600.jpg

Description: pots stacked in the kiln ready to fire [Thumbnail for IMG_1193-w600.jpg]](/t/57962/a/42211/IMG_1193-w600.jpg)

![Filename: IMG_1200-w600.jpg

Description: a view of good wood for firing this kiln [Thumbnail for IMG_1200-w600.jpg]](/t/57962/a/42212/IMG_1200-w600.jpg)

![Filename: IMG_1201-w600.jpg

Description: the firebox is too bright to look directly into for long, well over 2000F [Thumbnail for IMG_1201-w600.jpg]](/t/57962/a/42213/IMG_1201-w600.jpg)

2

2

1

1

Glenn Herbert wrote:Just back from my two weeks selling pottery and doing medieval recreation things... thanks for the nice comments, and for taking my work as a model.

You could make firebars of clay, dry them, and set them into the sides of the kiln for support. A more direct method is to make an arch of a green flexible stick, poke it into the sides to be stable, and wrap cob around it so the bottom surface is an arch and the top surface is flat. The stick supports the clay until the clay is dry enough to support itself. Using this method, I have numerous times fired a kiln for the first time loaded with pots sitting on the firebars - no need to prefire the kiln. It just takes a bit longer to do the first firing as you are drying and firing the kiln too.

| I agree. Here's the link: http://stoves2.com |