“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

1

1

"Rather than a problem to be solved, the world is a joyful mystery to be contemplated with gladness and praise." Pope Francis

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

John Weiland wrote:Finally getting around to posting photos of Exhibit A. The problem project here is a 40 X 80 quonset that is sagging in the middle. The internal photo is of a separating wall that was installed to keep the front half of the building insulated and warmer than the back half. A large canvas tarp once hung down to serve as the divider. The beam that looks split is actually a few overlapping 2X6s....I can't imagine they were really placed there for structural integrity of the roof, probably just serving as a header for the door frame.

Would love to have the middle rib of the building jacked up past straight, so that the roof would bow upwards a bit in the middle instead of downward. The only thing I could envision was some high strength cabling spanning from one side to the other and anchored into a few of the ribs somehow, but worry about the stress on those timbers.

Any thoughts? Thanks.

1

1

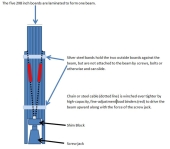

Glenn Herbert wrote:Short of a row of posts running down the middle of the quonset supporting the ridge, I think the only practical reinforcement would be cables, and there would need to be a cable at each rib pair so as to keep the stresses evenly distributed. I think the cables, if they went straight across, would want to be around the level of the top of the rollup door in the end wall. Unfortunately, that would be rather in the way of a lot of normal uses of the space. You might be able to make cable trusses with struts reaching down from the ridge, looking a lot like a series of drawn bows with arrows, with the cable attachments near the level of the bottom of the upper windows or top of the lower windows.

The cable ends would have to reach around each rib to bear on the outer surface beneath the roof sheathing, so as not to weaken the ribs by drilling holes or putting delamination stresses on them.

Anything like this would need calculations by a PE or other professional to size and locate elements and connections correctly.

In the late 17th century, the discovery for creating the strongest form of arch was realized. Robert Hooke had stated he found “the true mathematical and mechanical form of all manner of arches for building.” Initially encoded by means similar to that of an anagram (abcccddeeeeefggiiiiiiii-ilmmmmnnnnnooprrsssttttttuuuuuuuux), Hooke’s studies would later be revealed and applied. His string of letters, when re-arranged, held the details; “As hangs a flexible cable, so inverted, stand the touching pieces of an arch” (Ut pendet continuum flexile, sic stabit contiguum rigidum inversum).

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

Again, thanks for great ideas and comments.

Again, thanks for great ideas and comments.“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

1

1

Dale Hodgins wrote:Did it come down hard enough to ruin everything inside, or were you able to salvage much of it?

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

2

2

'What we do now echoes in eternity.' Marcus Aurelius

How Permies Works Dr. Redhawk's Epic Soil Series

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

|

Have you no shame? Have you no decency? Have you no tiny ad?

The Communities Directory at IC.org

https://permies.com/wiki/190212/Communities-Directory-IC-org

|