2

2

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

3

3

1

1

Shaz Jameson wrote:This is absolutely amazing.

The first thing that comes to my mind is using vegetable inks and printing out permaculture leaflets / one page flow charts for dummies and selling that as well.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

1

1

2

2

I'm looking forward to anything else you run across.

I'm looking forward to anything else you run across.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

Necessity inspires invention, and 17th-century Dutch papermakers looked for alternatives to the water-powered stamp mills used in Germany. Though the name is lost, and the date is in question (between 1660 and 1682), we know that an inventor in Holland eventually came up with a method for beating pulp that required no river power, did away with the additional time-consuming step of fermentation, and produced a higher quality product. The machine this inventor produced is today named simply after its country of origin.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

Shows how to make paper for painting, drawing, printmaking, sculpture, etc. In step-by-step photos, leading artists demonstrate their favorite methods and techniques.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

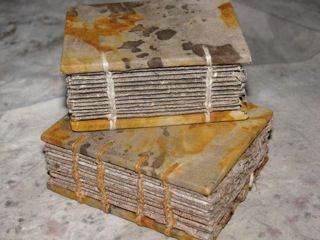

Velma Bolyard wrote: I sewed the pages into the cover with a traditional stationer's style of binding which dates back to medieval Europe. Thus the book includes pages made from many papers, including day lily, cotton rag, iris, hickory, hosta, slippery elm, dogbane, and others.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

2

2

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

We are passionate about our portable studio model, which is the cornerstone of Peace Paper Project. It is not just about convenience; this system has become our passport to connecting with international communities. The benefits of hand papermaking are most clearly experienced first-hand, so it makes our work all the more accessible to have the equipment that we use handy and easy to transport.

This page is dedicated to the resources, materials and approximate costs for developing a portable paper studio.

We invite you to contact us if you have any questions regarding information on materials, scheduling a visitation by Peace Paper or taking advantage of our training opportunities.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

2

2

2

2

William Bronson wrote:Not me, but it looks like it could be a great tool to get fibers for natural building or papercrete.

"We're all just walking each other home." -Ram Dass

"Be a lamp, or a lifeboat, or a ladder."-Rumi

"It's all one song!" -Neil Young

2

2

Judith Browning wrote:The Hollander beater is the expensive part of the process and is the thing that blocked me from going ahead with it. Now, I've gone on to other things but I still thing this is a good idea for a home based business. I think someone with a lot of skill could build the beater part or it might be a project for a Kickstarter campaign for somebody.

2

2

|

That's my roommate. He's kinda weird, but he always pays his half of the rent. And he gave me this tiny ad:

Support permies and give beautiful gifts to gardeners: permaculture playing cards.

https://gardener-gift.com/

|