I don't own the plants, they own me.

1

1

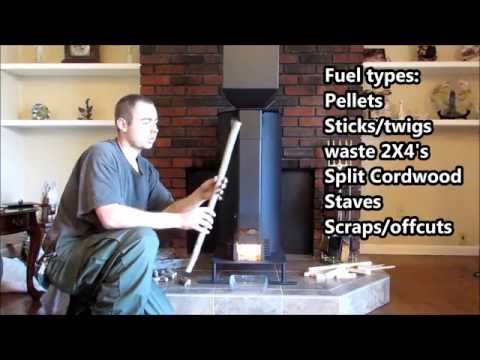

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

Eric Hammond wrote:I used single wall hvac pipe out of the mass up to where I penetrated through the wall

I don't own the plants, they own me.

2

2

Matt Todd wrote:

Eric Hammond wrote:I used single wall hvac pipe out of the mass up to where I penetrated through the wall

Where did you fall on the "galvanized fumes = bad" debate? Or did you pre-cook (oxidize) your galvanized HVAC pipe before installing?

Wondering if I should go with black stove pipe into my mass and up to the ceiling before transitioning to double wall above the roof as this thread encourages me to do.

Daniel Ray wrote:Matt,

after you run the gases through your bell--either using ducting or a stratification chamber--you can bring them up to the ceiling using single wall stove pipe.

I don't own the plants, they own me.

1

1

Matt Todd wrote:So the question now is: is the inside of a metal bell too hot for black chimney pipe, usually rated at 800 degrees F?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

| I agree. Here's the link: http://stoves2.com |