4

4

5

5

2

2

You could even have a sliding door that isolates the collection chamber and allows you to quench and cool the biochar before its removal.

1

1

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

2

2

2

2

William Bronson wrote:

Crap, I just realized, I'm describing an un-insulated batch box rocket with the door on the "wrong end", optimized for incomplete combustion by limiting oxygen with a progressive flame front...

2

2

4

4

2

2

1

1

Curtis McCue wrote:

It should be possible to incorporate an auger to automate loading. The tricky parts will include 1) synchronizing the feed rate to the rate of pyrolysis (it will depend on the type of material, moisture content, packing density, etc),

and 2) figuring out how to automate removal of the finished biochar.

3

3

Ellendra Nauriel wrote:Infrared sensors to track the pyrolysis front as it moves through the fuel? If a heat-sensing camera can show a person through a brick wall, it should be able to show a flame through a metal wall.

1

1

Check out Redhawk's soil series: https://permies.com/wiki/redhawk-soil

2

2

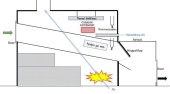

Curtis McCue wrote:Here is a quick sketch of what I have in mind for a manual continuous system (not to scale). PNG for viewing, SVG for editing

Ellendra Nauriel wrote:Anyway, picture one of those self-feeding pellet stoves, but with a funnel-shaped burn chamber along the lines of a kon-tiki. At the bottom of the funnel is another auger, treating the burn chamber as if it were a hopper, and feeding the hot char through to a dousing chamber.

| I agree. Here's the link: http://stoves2.com |