Hello, Jeff here. Long time lurker, first time poster. I've been here studying to build a RMH at home. I've been dissuaded from the basement so it'll be for the workshop/greenhouse or outdoor seating, maybe on the front porch. We live in a neighborhood where the houses were built back when people were generally more social so the porch is a good one (concrete and brick and big).

Anyway, I'm also interested in biochar and noticed this thread. I want to make sure I understand your setup. I think the steel vessel in the third picture is your retort which sits on the angle iron and the flue gas from the stove passes around but not through the retort. Put another way, the pipe going off the top of the second photo is a chimney for the retort only, not for rocket stove gas. Is that right?

If so and you get the load to char, I think you'll get a lot of pretty nasty exhaust out the top of it. That's all unutilized fuel ... and nasty.

The second photo in

this thread shows a way to get at that fuel that seems compatible with your setup. Once pyrolysis begins, combustion of exhaust gasses in the burn tunnel could eliminate the need for additional wood fuel at some point if well designed. A chimney like yours would probably help it draw better. But I imagine quite a bit of gunk could condense out of the smog on the way down that pipe to the burn tunnel so I have to wonder if it's prone to clogging.

Two years ago, I taught my 7th grade class how to make biochar using the instructional materials found

here. We made TLUD stoves out of soup cans and developed a rubric to evaluate the charcoal. These were scaled down versions of the type linked to by John Elliott earlier. It was a BLAST and I will never again hesitate to teach kids about fire in a serious and intelligent way (we did it in science class).

At the end of the project, students shared some of their research on other ways to make biochar. There's some pretty sophisticated, hand made systems being used out there, but I like simple.

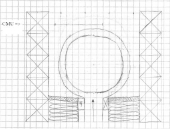

This is one of my favorites, sort of a collapsed version of yours. An L- shaped rocket stove is built right into the retort itself. The heat riser is not insulated and becomes the heat exchanger for the load in the retort. The pipe out it's top is from the rocket stove, not the retort and there's a small port from the retort into the burn tunnel near its mouth. Once the wood releases enough gas to produce a steady flow, it keeps the process going without additional wood though I suspect it gets hot enough to burn off some of the carbon rather than leave it as charcoal. It seems well made to me but looks like it might be dangerous which definitely got the kids' attention.

Some students proposed building one of these and a barrel sized TLUD to see if one did a better job than the other. An accessory for a J-type rocket stove such has you have built would be an interesting comparison too. But alas, summer arrived and I didn't teach science the next year. There are still photos of kids firing their stoves hanging around the school. I wonder how many of them could still describe what's going on in the stove or detail the differences between the pyrolysis of the wood and the intense after burn swirling around the secondary air ports. They've all continued to high school but I still see some of them. I'll ask.