posted 12 years ago

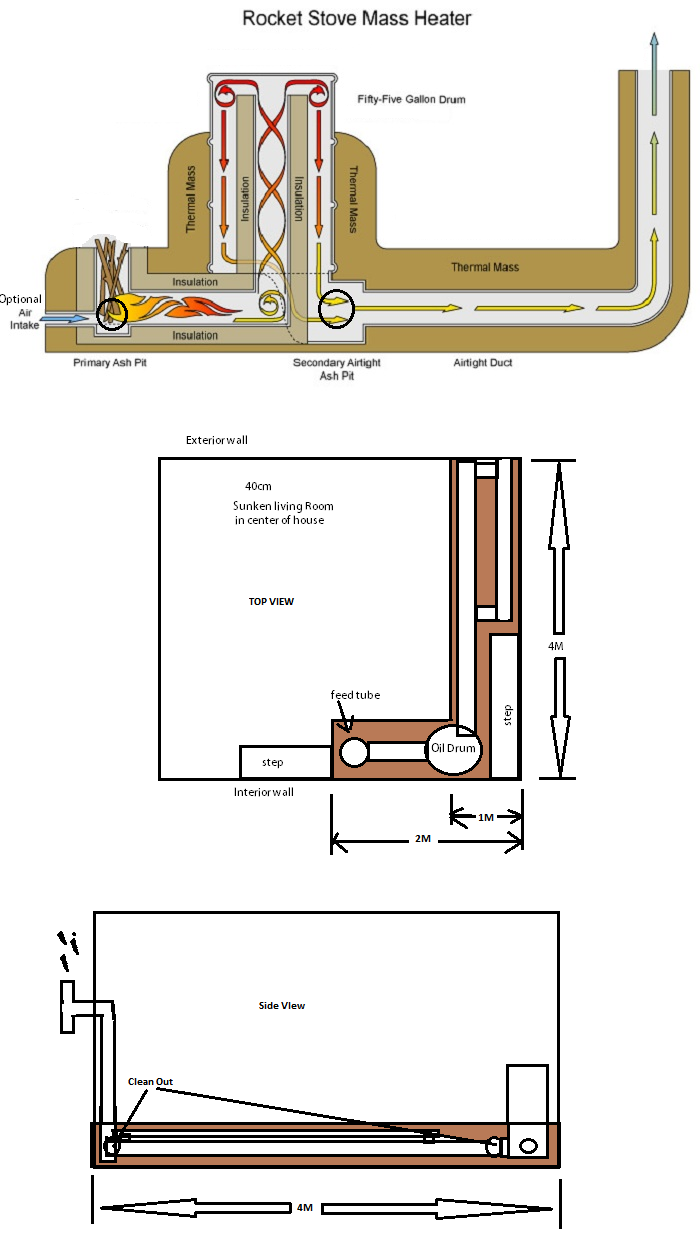

Hello people, I have been a memeber for about a year now. For about the same time I have been working on a 4 inch J stove for my small building I use by my trailer. I made it out of 1 and a half 30 gallon steel drums. Inside of it I used 2,600 degree refactory bricks for the feed tube, burn tunnel and the riser. I had the riser stop 3 inches from the top of the drum. I also add a inverted cone to the top of the drum. Hoping it would help the flow around the top of the drum be more even and not dead head the flow. I added window in front made from 1/4 inch thick ceramic glass. I used two sheets of glass and a 1 inch none sealed air between them. I placed a cooking stone on top of the drum. I then got two stainless steel deep bowls and add a heat blanket between them. I have cooked both pizza and breads on top. They come out very good and have a nice crisp crust to them. When I am not cooking I keep the lid off the stove. Hoping to pull more heat from the drum I welded 3/4 inch angle iron to the drum and then screwed 1 inch copper pipe to that. The bottom of the pipe run about 75 degrees colder then the top, seems to pull the colder air up the pipe well. In the burn fed tube I get get the temps upto 1950 degrees F. My gun stops after that. I ran about 6 feet of 4 inch chimney total. The stove starts very fast, the draft is great and so far no smoke backing up into the building. The building is around 160 sf. I did do a good job of insulating it. I placed sheet metal behind the stove to reflect the heat back into the room as much as I can. The stove has no problem heating the room to 84 degrees inside with outside being in the 30s. Thanks Nick in NJ.

rocket-stove-4-inch-j-stove.jpg

rocket-smoke.jpg

photos-of-stove.jpg