Hello. Hope I can help ya.

Here is my rant :

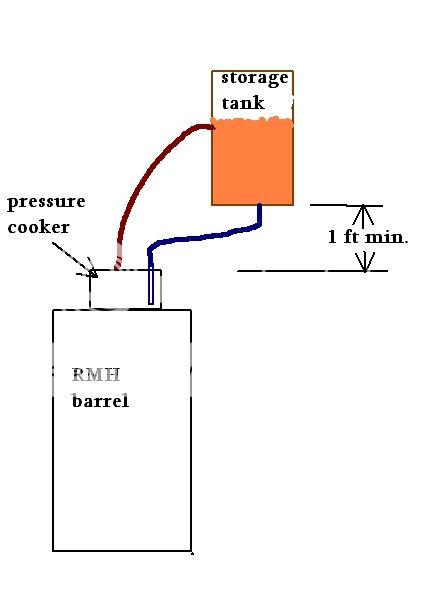

When I came across the problem of how too heat water, I did not want any pressure developing, and at some point, when I install a storage tank, it will have a 1/2 inch copper water pipe - starting at the top of the tank - going up too the roof, and outside thru the wall. So, not only will it vent out any steam, but it will vent the steam outdoors, so I will not get any mold or mildew inside the structure. The tank will only be 4/5 ths full of water, that way any steam or explosive water heating (turning on pumps on a hot stove) will be expelled inside the tank, and you will not get any liquid water in the vent tube - it HAS to be kept clear....

I also had too answer the question of how long of tubing. . .

I wanted good coverage of the barrel, and each round of the barrel is about 3 feet or so, so I winged it and I believe I picked up a 50 foot role of flexible 3/4 inch tubing. It covers about 1/2 to 2/3 of the barrel (loose fit) and it's big enough too have low water flow resistance - filling up or draining out. I have already tried to build a solar water heater out of 1/2 inch piping, and you get very little heat transfer (not enough liquid in there) and very poor water flow - 1/2 inch pipe would be too small and offer more resistance. You could go with 1", but that is costly stuff.

The next question that came up was internal tubing or external tubing. . while the external tubing is a rather loose fit, the internal tubing idea - with the tubing inside the barrel - I feel - would cause too much turbulence in the air stream and possibly block the stove from working to it's full potential. It would also be a nightmare too clean out if needed.

Yes, I do have a drain back system, and I am planning on having the larger storage tank sitting on the floor beside the stove - with the above mentioned vent pipe going thru the wall - so the stove heats up, water gets pumped around - steam goes thru the wall - if anything shuts off or you forget to plug in the pumps - the copper tubing is dry - and it radiates the heat into the room.

If you are going to be constantly using this set up for heating freezing water, I would heat up the stove first, then turn on the pump - so you have the draft going. You can't boost the draft if it's not warm yet.... and yes, I have found with a block of ice in the water pail - the thing just ROCKETS !

I am planning on using this set up here - as a snow melting system - since it only improves the draw of the stove - the colder it gets . . . As for Ernie's advice of soot and build up, I do have too agree, that with a full water jacket replacing the barrel, it would absorb a huge amount of heat.... but with my tubing, it is barely touching the stove (that stuff is hard to bend ! ) and only absorbing the heat the barrel is loosing anyways . . It does make sense, that if you cool the gases too much, you will get build up inside the stove, but on the other hand, if the stove is rocketing better and faster - hotter - would that compensate ? I will have to watch the RMH videos again - where does the re burn / after burn take place ? If all the gases are burnt in the riser and at the top of the barrel - can you extract the heat from the middle / bottom of the barrel ?

The smartest thing I have ever heard someone say - I will say to you now :

I do not know.

O.k... now that - that is out of the way . .

You ask - should I go with 1.2 or 3.

I would look at the negatives .. and take the best option :

#1. inside - how would you clean it. This is a wood burning device - your going too have too clean it out eventually. A full water jacket would extract too much heat and possibly effect the operation of the stove.

#2. outside the barrel does not look pretty, and you do not get the super hot - heating affect as you would right in the fire, but it's clean. - you also have the option - which I have not tried yet - of wrapping a piece of sheet steel around the outside of the tubing making a super heated air space for the tubing. The air would still be able to rise and exit the top of the spacing, it would just concentrate the heat around the tubing instead of radiating past it. Again, how would it effect the draw of the stove ? Without the heat radiating from the barrel would it slow the draw ? I am going to have too try this one and find out . . .

3. I am not sure about trying too heat water too far from the stove. Yes - there is a definite point too having all kinds of nasty build up inside the stove if you cool it too much / too fast - like replacing the barrel with a full water jacket - but I know from taking temp readings from my stove, that while the top of the barrel is 1,000 degrees - it quickly falls off to around 400 at the very bottom of the barrel, and then at the very end of the line the exit temp is barely 180 (for my stove - without water running).... so the further you get away from the heat source, the less latent heat you will be able to collect . . make sense ? I might add as a side note . . . I am not sure I posted this in my thread, but I believe the chimney temps were hotter when pumping ice water thru the system - better rocket effect - faster moving/hotter air inside the mass . . . I will have too check on this for you this winter . .

The next item is temperature. In my example, I have blocks of ice floating in the water pail. You will get a totally different outcome by raising that temperature. Higher temperature in the coil would suggest less radiant heat absorption - so more heat would go into the stove / less soot build up. 140 degree F water is a far cry from 32 degree water . . What would the return temp be for your system ? - That is what would be going thru the coil. So 100 degree water going thru the loop may not have very much effect on the draw of the stove . . again - I do not know .

The question of pressurized water is always there, and I know from experience (and also having an open ended pipe dropping into an open pail) that if you turn on the pumps on an already hot stove, you do get explosive ejections from the end of the pipe as the first few liters of water flash too steam - something else too keep in mind. - but then having a storage tank that is 4/5 ths full (lots of expansion room in there) - with an exhaust outside should compensate for that . . I am thinking - have the return from the stove (with the explosive steam) enter into a 3/4 inch "T" the bottom of the "T" dropping directly into the top of the air space at the top of the tank, while the top of the "T" will have a 2' piece of copper 3/4 inch that then reduces too 1/2 inch. That way, any high pressure bursts will have the room too compress the air in the top of the tank, but also have space to expand into the upward part of the air vent - without actually entering the 1/2 inch portion of the vent. Just an idea...

And finally, in your last post you quote the temp of 140 F - you are right, that is the max. Even after a 3 hour burn, the make shift pails with no lids on em (wide open) lose too much heat . . so with the setup that I have here, 140 F is as high as it will go. The hotter the water - the less effect it had on the stove, it was just circulating sustaining that temp . .

I did want too try wrapping the copper tubing with a sheet metal jacket - figuring that if I can get this setup to 150 or 160 - heck - even melting the pails - then I know I will have a system that will be worthy of investing in - i.e. buying the low temperature radiator / tubing for in the house.

But then that's just me..

This is just my opinion, hope it helps.

Let us know what experiments and projects you come up with....

and of course the warning of pressurized water :

I love that picture

1

1

![Filename: 20140809_121306.jpg

Description: [Thumbnail for 20140809_121306.jpg]](/t/49468/a/33431/20140809_121306.jpg)