5

5

3

3

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

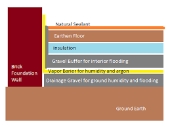

Scott Lawhead wrote:I am planning on using perlite insulation under my earthen floor. Does anyone have experience with this material?

Build it because they say you can't.

18 different architect's that said " you can't do that "

Google " undergroundandlovinit "

3

3

11

11

3

3

3

3

6

6

Scott Lawhead wrote:The platform shoes were definitely necessary while leveling… it did compact more than we thought, we meant more roadbase on top of it (so.much.wheelbarrowing). There is 8” of drainage rock underneath it, with a commercial grade vapor/radon barrier between drainage rock and perlite.

It amazing, and unfortunate, that as many natural building systems one uses, it still comes down to a big sheet of plastic between the building and the earth, and a big sheet of plastic between the building and the sky. It’s debated on forums, but I think for longevity and reliability, a vapor barrier underground and a waterproof membrane on the roof is absolutely necessary.

Earthen floor is in a couple weeks! Need to install below grade plumbing lines and radiant tubes, but it’s close!

1

1

2

2

7

7

1

1

1

1

Become extra-civilized!

|

No one can make you feel inferior without your consent - Eleanor Roosevelt. tiny ad:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|