11

11

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

9

9

Silence is Golden

For all your RMH needs:

dragontechrmh.com

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

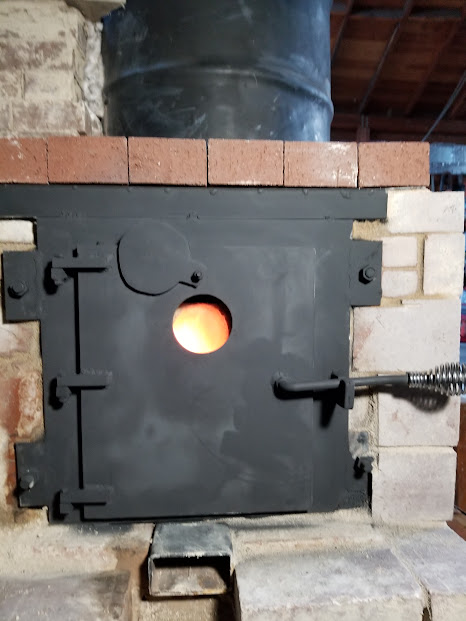

thomas rubino wrote:Yes, it does!

Check out the new shop batch box build at Wheatonvile.

https://permies.com/t/193821/permaculture-projects/inch-batch-box-rocket-mass

The funny thing is, I would have told you not to do it two weeks ago.

I was under the impression Peter wanted a flat roof on batch boxes.

He recently said using an arched/domed-style roof was okay.

4

4

|

My cellmate was this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|