Any thoughts on where to best place a water coil for a thermosiphon loop?

I'm hesitant to place it in the burn-tube, as I don't want to crash the temps, and putting a loop in the burn-tube is

difficult to design while avoiding any downturns in the plumbing to avoid heat traps or live steam. (NO ELECTRIC PUMPS!)

If a coil is placed on the outside of the drum, that seems very inefficient with the low temperature delta.

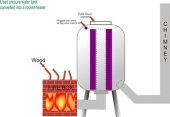

This leaves a couple options; coil hanging on the inside of drum/bell, or a coil wrapped around the Vertical Burn Chamber just

prior to insulation.

I like the later, as this will keep the Vertical Burn Chamber (made from stainless pipe) cooler, and any soot build-up will

be easier to brush free from the inside of the VBC, where one would expect it to condense, rather than having to fiddle with

scrubbing a long & unwieldy loop of copper tubing. (Monotube boilers are a bitch to clean without the aid of a steam lance.)

One-inch copper thermosiphon tube should move enough fluid to prevent steam cavitation. Thoughts?

My design will not include a cob mass bench. After the bell, it will exhaust straight up thru the roof. My cabin is two stories,

380 square feet. Stove will be located downstairs. Water loop will thermosiphon to a tank. Warm air will cycle by convective

loop thru a large grate and stairwell. TP valve near stove, mixing valve on storage tank for safety. YMMV. I'm located in

the NW USA.

Failing this, I've got a 15 gallon stainless beer keg, and I'll make a batch heater using something like Erica's canning rocket stove:

https://permies.com/t/18988/stoves/Erica-Wisners-Rocket-Canning-Frying#161360

!~~_3.jpg)