8

8

7

7

7

7

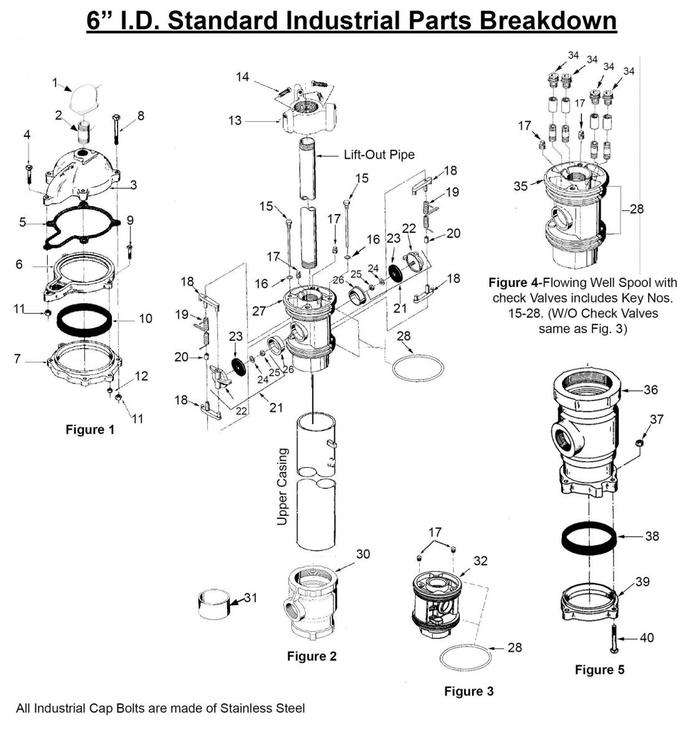

Its a spool type pitless like a Baker Monitor standard.....most that I've seen on wells less than 8" do not have any sort of lock mechanism, they simply rely on gravity to seat the spool. It so badly corroded, I bet that is your problem pulling. We pulled one few months ago that was very corroded....the weight of the pump assembly was 5800#, and it took over 13000# on the crane to unseat it. Also, this type can be much harder to pull if you aren't pulling straight, which you probably weren't if you were using some sort of jack. Pull straight and pull harder, use a good pull pipe and screw it in very tight.

The step in diameter is on the bottom of the spool....there are 2 steps actually, the top and bottom of the spool both seat...the bottom is the smallest diameter; that means, the spool will unseat, but will basically be tight all the way up because of the rust. On a new unit, the orings will just barely touch the casing sides as you lower it...then it seats about the last 1 inch. This looks like maybe somebody has been chlorinating the well and not rinsing??? You should try to get new orings, as you will probably need them; we use vaseline to lube thenm. It's hard to say what the drop pipe is; we never use these on residential because they are expensive....What size pump do you have? I would not try to clean the casing first, as most anything you loosen up will fall down on the pitless spool. You mentioned possible damaging the spool....yeah, it's possible, but I've pulled really hard on these before and never had a problem.....

5

5

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

4

4

2

2

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

thomas rubino wrote:What about a chain fall (come-along) hooked to the stationary bucket?

9

9

Beau M. Davidson wrote:I don't have a crane, so I'm trying to figure the best way to get a straight vertical pull with the best power from the tractor bucket. Thinking of chaining between the arm at tractor center directly behind the bucket, and starting as low as possible. A little tricky, as there's a yard hydrant right by the well.

![Filename: 71AgM5SmCML._AC_SX569_.jpg

Description: [Thumbnail for 71AgM5SmCML._AC_SX569_.jpg]](/t/274877/a/260799/71AgM5SmCML._AC_SX569_.jpg)

5

5

![Filename: lifting-with-hoist.png

Description: [Thumbnail for lifting-with-hoist.png]](/t/274877/a/260802/lifting-with-hoist.png)

![Filename: IMG_9391.png

Description: [Thumbnail for IMG_9391.png]](/t/274877/a/260803/IMG_9391.png)

![Filename: IMG_9390.png

Description: [Thumbnail for IMG_9390.png]](/t/274877/a/260804/IMG_9390.png)

![Filename: lifting-with-hydraulics.png

Description: [Thumbnail for lifting-with-hydraulics.png]](/t/274877/a/260805/lifting-with-hydraulics.png)

7

7

5

5

Beau M. Davidson wrote:Psyche.

Turns out this is another case of "the right tool makes all the difference," laced with a bit of "a railroad plate and threaded rod makes you stronger than a John Deere 4020."

We called upon local expertise and were able to get the pitless adaptor out. Here's how it went. Not pictured is the cheater bar and the rod by itself.

|

We're all out of roofs. But we still have tiny ads:

Extend your growing season with the Hotbed Plans eBook + Self Heating Winter Greenhouse Plans eBook

https://permies.com/wiki/192368/ebooks/Hotbed-Plans-eBook-Heating-Winter

|