2

2

Trane DePriest : Welcome to Permies.com, our Sister Site richsoil.com, and a Big Welcome to the Rocket and Wood Stoves Forum/Threads !

You should be able to come here nearly 24 / 7 and talk to someone who wants to talk about what you want to talk about ! You definitely think outside the

box, we need a lot more people like you who think this way, thats what makes us grow !

The most hopeful thing I see about your build is the amount of care and attention to detail went into the areas you thought were important ! After your

final vertical chimney leaves the basement it enters another ?Brick? chimney, this chimney should have been checked by a Chimney Sweep or other

qualified person, the total vertical distance of your basement stove pipe and the exterior chimney should work for you For natural draft! For any fan the

reverse is true, and an unlined vertical chimney will oftenBe laid up by a mason that puts his very best work into making sure the chimney is pleasing to

the eye, level and plumb, have consistent mortar lines where the excess was struck off, and be ruff as cob and nasty on the inside where no one would

be likely to pass judgement on that quality of work for years and years !

I have reputation as an old crab, in this case I am going to ask you to verify about every step on the building process!

You need to disassemble the Vertical Stove Pipe in your basement, and get into a position where you can hold a mirror inside the bottom of the ?Brick?

Chimney during a brite sunny day you should be able to clearly see much of the upper third of your chimney and inspect for intact tile if any, and the

light outlining the top of the chimney as seen in your mirror should be sharply outlined with nothing blocking the light, It should extend 5'-6' over the

peak of the roof ! and get rid of or move the piece of wood hiding behind your vertical Stove pipe, It looks too much like amateur hour !

It is possible that you have an outside clean out at the very bottom of your Exterior Vertical Chimney and can check your chimney from there, Warning

The old clean out may be cemented into place with a furnace cement and be in very poor condition ! After your inspection this must be sealed up again

tight !

You mentioned that you had read about increasing the height of the Barrel and the Heat Riser, this will indeed increase the Draft created by the Heat

Riser, In an ordinary system you would then worry that the draft was too strong, sucking the hot exhaust gases out of the Combustion zone (my word choice)

before all the hydrocarbons were 'burned '. this is not your problem, a 1/3 of a barrel at a time is a lot, with a barrel and 2/3rds disassembling the barrel

for cleaning will be a two person job ! While I don't think that you will even hit the ceiling with that barrel, it is possible to knock the fire bricks of the

Heat Riser loose and never know it until you take it apart and check it for level and plumb ! again a 1/3 of a barrel at a time is fine a 3'' gap on a taller

barrel is good enough !

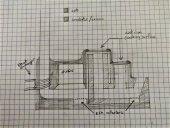

Lets talk bricks The only place I can see any bonding material is in your shot straight down inside your barrel where there appears to be some Mastic of

some kind, In your pictures i see no sign that the bricks are sealed up with any thing, a simple leak of exhaust gasses certainty if the bricks were just

stacked up into a running bond without any effort to seal the spaces between individual bricks, thats a minimum of 3 sides out of 6 for each brick more

with pieces!

Not to be missed you need to verify the type of brick you have, you will need to measure them and report their sizes and then weigh 10 of them on a

bathroom scale or drop by the Post office (or Ups, Federal Express, or a similar clone,) and ask them to weigh a brick ! This will calm some of my darker

fears !

Two last things, please goto> rocketstoves.com to Download your PDF Copy $15 U.S. of 'The Book' "Rocket Mass Heaters'',this will allow you

have a source that explains the ratios between heat riser height, and Feed tube and Burn Tunnel Length and how to actually determine the Constant Cross

Sectional Areas, and the need to keep them constant !

I also want you to google stack effect in houses so that we can talk about it later !

We have a lot of work to do, But if you are committed to having a Rocket Mass Heater RMH, In Your House, your fellow members here at permits will help

you make it happen ! for the good of the craft ! BIG AL !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

2

2

"Necessity is the mother of invention" That's why I'm a Jack of all trades, Master of some and have learned that Knowledge is power, but information isn't necessarily knowledge.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

|

Cat talks about fish. Like it needs a fix. This tiny ad told me to never say "fix" to a cat person:

Back the BEL - Invest in Permaculture

https://permies.com/w/bel-fundraiser

|