God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

It is sort of funny how one can envision a product and its design, yet find it difficult to explain it. While for others the opposite holds true.

Paul Ebert wrote:

i was sent a link to the "Dragon Heaters" site.i like the looks of their Castle built model.Any opinion on them?

How permies.com works

What is a Mother Tree ?

Burra Maluca wrote:

Paul Ebert wrote:

i was sent a link to the "Dragon Heaters" site.i like the looks of their Castle built model.Any opinion on them?

I sincerely hope you're not telling us that a member is using the PM system to advertise their own site as that would be a gross abuse of membership. Possibly a banning offense. I trust it won't happen again.

www.dragonheaters.com

http://blog.dragonheaters.com/

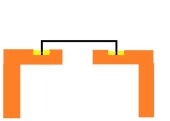

Cindy Mathieu wrote:If you are building a rocket heater on a wood floor, you need to incorporate an air gap between the wood and your burn tunnel. The layers might be the wood floor, stone, bricks to create air gap, another piece of stone, then, the burn tunnel. A detailed recommendation for this is found in the 3rd edition of Rocket Mass Heaters on page 68.

The burn tunnels do get very hot and because the fire is usually down lower than in a cast iron stove, the wood floor is subject to spontaneous combustion without proper precautions.

I would still use one in my application to assure the floor doesn't get too hot.

www.dragonheaters.com

http://blog.dragonheaters.com/

Maybe I'm overthinking this,hah.

|

Please all, and you will please none. - Aesop / tiny ad

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|