Its been awhile since I've built a stove. I found that the gravity feed that I used in my outdoor rocket boiler, while it worked and was reliable, it was inconvenient to use. Bundling wood and dropping it down a 7 ft tall stack isn't fun when there is snow and its freezing cold outside.

I set out to build a stove that would be clean burning, not need constant attention, and be built with common materials. What I've ended up with is a hybrid between a wood gasification stove and a rocket stove. Even if smoke, soot, and smell is absent from exhaust, there can still be combustible gases such as CO, H2, and CH4 that are invisible and odorless. This became evident to me through a small rocket stove I built from a exhaust elbow inside a metal paint can. The inside was insulated with perlite. I noticed flame jets popping up around where the exhaust pipe came out the lid of the paint can. I believed this to be caused by heated air inside the paint can combining with unburnt fuel being exhausted, much like a wood gas stove.

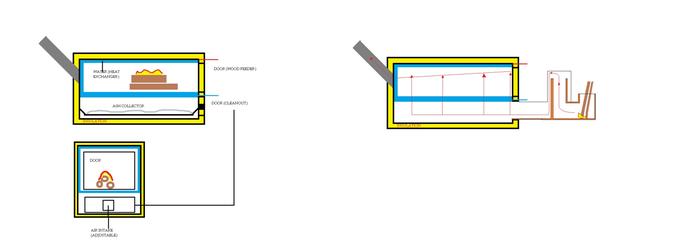

This observation inspired me to add a secondary air injector to the heat riser of a rocket stove.

To get longer load times, I've constructed a larger firebox designed to burn entire logs at a time. The logs gasify inside the firebox and the wood gases are then channeled to the heat riser. They mix with air from a secondary air injector where they spontaneously ignite, thus providing clean combustion. Air temperatures from the air injector range between 650 and 700 C.

Here's a video playlist I put together on my prototype stove:

https://www.youtube.com/playlist?list=PLq-ETrB2scGG_tQBeuGbiVTXGIDTEnFuX

This small stove puts out a peak of 31K BTU and lasts 1.5 hours between needing to be reloaded. When you consider the only insulation this stove has is the concrete block that makes up its body, the clarity and lack of odor of the exhaust is quite impressive. It definitely works well as a outdoor cookstove.

In my full sized version, I will be insulating the firebox and heat riser to hopefully obtain even better results. Calculated run time with the larger firebox is 6 to 8 hours. Waste heat from the stove body will be reclaimed to further preheat combustion air, both primary and secondary. Heat will be extracted from the exhaust gas at the top of the heat riser by means of a firetube boiler (non pressurized) and pumped to an exchanger.

I hope you enjoy the videos on my little project. I'll be doing more videos on the larger version that I plan to heat my house with this year.