My PEP Badge Tracker: An easier way to track your PEP Badge Progress

will be released to subscribers in:

soon!

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

1

1

It's better to keep your mouth shut and appear stupid than open it and remove all doubt - Mark Twain

The other one is a foot in diameter and about 50 inches tall.

Hans Albert Quistorff, LMT projects on permies Hans Massage Qberry Farm magnet therapy gmail hquistorff

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

Jake Parkhurst wrote:Scrap that last post if you actually want to use the water as water and not just thermal mass.

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

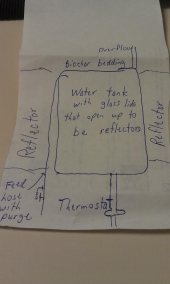

![Filename: rocketstove.png

Description: The configuration in #4 is closest to what I have in mind [Thumbnail for rocketstove.png]](/t/52991/a/35660/rocketstove.png)

positively optimistic 🙂 https://www.youtube.com/@613Builds

2

2

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

1

1

1

1

Rocket Mag evolution timeline: http://www.permies.com/t/52316/rocket-stoves/Rocket-stove-heats-water-pics

Rocket Mag Thread: http://www.permies.com/t/54074/rocket-stoves/Rocket-Mag-heater-Rocket-Mag

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

positively optimistic 🙂 https://www.youtube.com/@613Builds

|

This is awkward. I've grown a second evil head. I'm going to need a machete and a tiny ad ...

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|