A batch box has a very specific set of dimensions and characteristics. What you first built was just an extra big L-tube, with the firebox twice the size of the rest of the system so that it had lazy draft and let a lot of the wood sit buried in upper coals and not getting oxygen. Reducing it to 8" cut the firebox area to less than half, so more than twice the draft speed, and better oxygen exposure.

Your bell system is apparently effective (how hot is the chimney exhaust out the top of the bell?), though I think there are some ways it could work even better.

If you put the two barrels with mass on top of the combustion chamber and riser, I think it would work at least as well while taking significantly less floor space.

The exhaust plunger tube occupies a lot of the bell volume, and there may not be enough internal space left for the bell stratification effect to fully manifest, plus the plunger is passing through the hottest part of the bell and picking up extra heat and taking it straight outside. Running the chimney out the bottom side of the bell just like you did with the first barrel would be more effective, and that pipe would be cool enough to not be a serious hazard. With a larger duct around it stuffed with rockwool, it should be entirely safe.

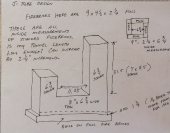

Lastly, a J-tube or a batch box would be more efficient at combustion than an L-tube, according to experimenters who have sophisticated testing instruments. I wouldn't advise you to scrap what you have, but if you decide to try another version, a 6" batch box which would only stick a foot or so out of the side of a two-barrel stack would give the same heating power as your current 8" system has, in a significantly smaller footprint.

Three barrel batch rocket, which could be done as a two barrel mass heater design with the firebox set lower and cob lining the barrels. The 6" batch box would only need 6" exhaust/chimney ducting.

1

1

1

1