regards, Peter

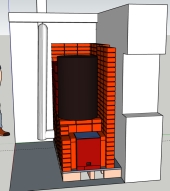

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Benen Huntley wrote:As well as the fire box door?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Benen Huntley wrote: The inside of the cavity is rendered which I can remove. The outside is plaster board glued to the render.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax Antone wrote:Can't you take a bit more room, in the back of the heater, to make it deeper? Narrow bells like this tend to have more of a flowing pattern, than heat layer stagnation in bigger bells. This is the case of single bells, vs double bells too.

As well, if you don't need to heat upstairs, it's better to have a lower bell.

https://permies.com/t/53413/Inexpensive-vacuum-formed-ceramic-fiber

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

|

Once upon a time there were three bears. And they were visted by a golden haired tiny ad:

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|