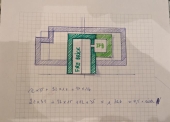

Rocket Mass Heater Plans: Annex 6" L-shaped Bench by Ernie and Erica

will be released to subscribers in:

soon!

4

4

![Filename: thumb-20230106_150656.jpg

Description: [Thumbnail for thumb-20230106_150656.jpg]](/t/234169/a/227043/thumb-20230106_150656.jpg)

![Filename: IMG_0068.jpg

Description: [Thumbnail for IMG_0068.jpg]](/t/234169/a/227044/IMG_0068.jpg)

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

2

2

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

3

3

3

3

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

3

3

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

5

5

![Filename: images-(1).jpg

Description: [Thumbnail for images-(1).jpg]](/t/234169/a/228336/images-(1).jpg)

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

1

1

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

Glenn Littman wrote:For the past few days I've been pondering the structural integrity of my planned 6" design of the brick bell/stratification chamber. The external dimensions are approximately 42" wide x 33" deep x 74" tall. I've done some brickwork repair in the past but I've never built a brick structure so I don't want to make a huge novice mistake.

Does anyone have any thoughts whether a single-skin brick structure of this height will be structurally sound? Does it need some form of structural support? My design height is dictated by the firebox being internal to the bell and 16" off of floor level with a 43 3/8" riser and 12" clearance above the top of the riser.

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

7

7

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

|

It's a beautiful day in the tiny ad neighborhood

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|