7

7

Become extra-civilized!

1

1

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

1

1

1

1

Nancy Reading wrote:Hi Coydon, sounds like an interesting project. I'm not sure why we don't hear more of floor ducted RMH so I wil be interested to hear how you get on.

My understanding is that sand makes for a poor thermal mass because the air gaps between the particles acts as insulation. If you found just a layer of sand was good enough for your previous heater, then it seems that you ought to be OK.

If I were doing it here, I would be worried about damp - water will conduct heat and turn to steam, neither of which sound desirable in a floor! But if your climate is drier, or you have a method of keeping the floor dry then that won't be an issue.

The other thought I have is that only the top of the mass will be radiating into the tipi, so you will lose some of the comfort factor from the sides of the mass. Maybe the positioning of the ducting in the cob will affect the heating and cooling of the mass, but I don't have any experience to suggest what might be better.

Become extra-civilized!

2

2

Coydon Wallham wrote:My proposed design is to have dirt/cob/masonry around the ducts filling the centre of the Yurpee footprint, then some sand underneath and around the perimeter, then some insulative rocky material like pumice (or perlite or vermiculite if better). Unless the rocky perimeter would be redundant since the sand is insulative and drains well, meaning I just need to make sure the dirt/soil is cleared out in a perimeter extending beyond the edge of the yurt.

What I've been told is that heat travels equally in all directions through solids, rather than rising like it does in gases or fluids. But my hypothesis is that if the bottom and sides of the floor mass contact insulative material, it will retain most heat and radiate it out of the surface,

The idea here is that the barrel radiation will keep the area warm while running (I will make it as low and unobstructed as practical), and the in ground mass will provide whole area warmth after it has warmed.

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

1

1

Glenn Herbert wrote:Just how flat and level is your building area? If there is not a place to run the perimeter ditch to, I would be more comfortable adding sand to get the mass above surrounding grade. Otherwise, it sounds like (with your natural conditions focus) you would be best off just removing all dirt so the sand can be maximally insulative. I would concentrate any insulation materials you do decide to use around the perimeter, as if the interior is continually heated above ambient there will be a much bigger gradient horizontally than vertically.

Become extra-civilized!

3

3

Coydon Wallham wrote: I think you are suggesting a thick wall to the cylinder around the floor, and a thin or absent bottom? Better to take the depth of the insulative sides down below the frost line and leave it exposed to the buried thermal inertia than to have shallow walls and an insulative bottom?

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

Nancy Reading wrote:It looks like the conductivity of vermiculite, pumice and perlite is about 10 times that of dry sand, vermiculite being rather more than the other 2. so you would need a much thicker layer of sand to get the same effect as with the porous materials. Even a couple of inches of perlite would make quite a bit of difference.

from engineering toolbox:

W/(mK) at 25oC

pumice : 0.02

perlite: 0.031

vermiculite: 0.065

dry sand: 0.15-0.25

dry soil (low organic matter): 0.33

gravel 0.7

Become extra-civilized!

2

2

Coydon Wallham wrote:

Thank you, I had no idea what terms to use searching. That is a nice compilation of relevant information. Where did you get the data number for pumice from? It isn't in the list that I pull up under that name, and nothing that sorts into the 0.02 level matches.

I'll have to dig into that site more as I'm also interested in using wood for insulating structures. I'm confused though because the Red Pine I'd like to use is listed 3 or 4 times with different numbers ascribed to it. I'm wondering how exactly they came up with the numbers for perlite and vermiculite. Is that just one solid rock, and how would size/configuration of multiple rocks affect those numbers? I'm assuming they are only talking about "expanded" perlite and processed vermiculite...

Depending on that number, pumice looks like the preferred substance, with perlite a close second. I can find mention of them shedding water or floating, whereas I'm reading about vermiculite helping to retain water.

I'm having trouble looking for pumice. Seems I can only find it in bricks for personal care or small amounts for horticultural use. Landscaping places I'm finding carry "lava rocks", which turn out to be scoria or cinder. Since pumice floats and scoria sinks, I'm thinking pumice is going to work much better as a layer in the ground by not becoming saturated. I'll have to call some landscaping places directly to see if it would be affordable to have available.

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

Become extra-civilized!

1

1

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

Nancy Reading wrote:Doh, can't find it now:

matmake.com give values of 0.21 - 0.5 W/mK

a pumice quarry in Ireland give a value of 0.32 for their pumice

Ha!

I think this is where I got it from:

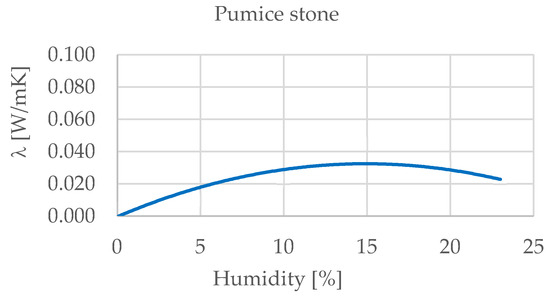

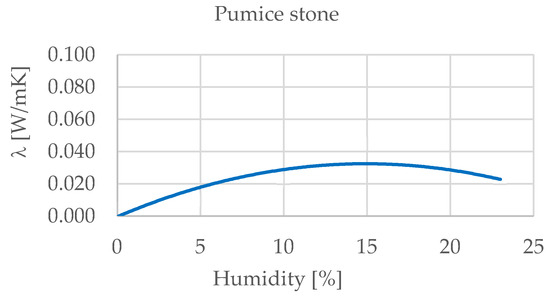

image source

This was from a paper on the effect of moisture content on thermal properties of building materials. I just approximated it to 0.2. This may not have been a loose fill material however, which may increase the insulative properties slightly.

Become extra-civilized!

Coydon Wallham wrote:Somebody is dropping a decimal place somewhere. That chart is showing .02, the other places are quoting .2. I see them switching between C and K, but that usually doesn't affect ratios. I would expect the higher number to come from concrete with pumice aggregate, but the matmake site seems pretty clearly to be just about the pure rock...

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

|

I am not young enough to know everything. - Oscar Wilde This tiny ad thinks it knows more than Oscar:

The new permaculture playing cards kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|