9

9

6

6

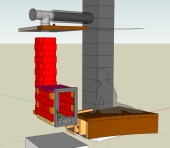

![Filename: CornerMasonryHeaterSlabReinforcement.png

Description: [Thumbnail for CornerMasonryHeaterSlabReinforcement.png]](/t/273286/a/258116/CornerMasonryHeaterSlabReinforcement.png)

6

6

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

7

7

6

6

12

12

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

8

8

5

5

Remy Fils wrote:I manage to find more information on RMH + hot water systems in the European forums. I was wondering whether in the USA hydraulic heating of rooms by radiators was a common thing?

5

5

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

4

4

7

7

John C Daley wrote:As a Civil Engineer, I am confident 100mm steel columns will work.

Have a base plate at the bottom to spread the load around, say 300 x 300mm x 10mm thick.

Using 100mm diameter pipe will ensure the L/ R ratio will ensure the column is not too slender.

A steel or timber beam at the top will spread the protection across the floor.

I consider Cristobal's suggestion of 4 / 400 mm brick columns overkill

4

4

thomas rubino wrote:Hi Remy;

Support columns are a good idea.

Have you chosen a build design yet?

A J-Tube with piped mass?

A J-Tube into a stratification chamber? (Bell)

A Batchbox into a bell?

Single wall bell or double wall bell?

All these choices will weigh differently and spread the weight over different areas of size.

Yes, you could continue with this thread.

However, I would start a new thread for your next questions.

Here is why: Your current thread addresses a very common question from prospective builders.

Any new questions you ask may be just as important, but they will be buried under a thread header of weight restrictions.

So, any perspective builder will bypass this thread, looking for one that covers their question on, say, the transition area (another common worry).

Cristobal Cristo wrote:Remy,

I would recommend to start the journey with estimating the heat loss of your house:

https://kalk.pro/en/heating/heat-loss-calculator/

I like this calculator, because it has a list of various masonry building materials that can be assigned any thickness.

It would help if you provided a plan for each floor.

With masonry interior walls, the placement of the heater is crucial.

5

5

5

5

4

4

5

5

5

5

6

6

5

5

5

5

Cristobal Cristo wrote:Remy,

For the area have you used the area of exterior walls?

Cristobal Cristo wrote:Remy,

Are the exterior walls over a meter thick (42")?

Cristobal Cristo wrote:

Are the concrete or hollow blocks or bricks?

Cristobal Cristo wrote:

You put 35" for the ceiling thickness. Is it some conversion error? The same for the floor.

Cristobal Cristo wrote:

Please provide house dimensions: length, width and height, and I will play with it myself.

6

6

6

6

6

6

4

4

7

7

8

8

4

4

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

|

There is no beard big enough to make me comfortable enough with my masculinity to wear pink. Tiny ad:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|