1

1

2

2

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

robin miller wrote:Thanks Gerry and Thomas.

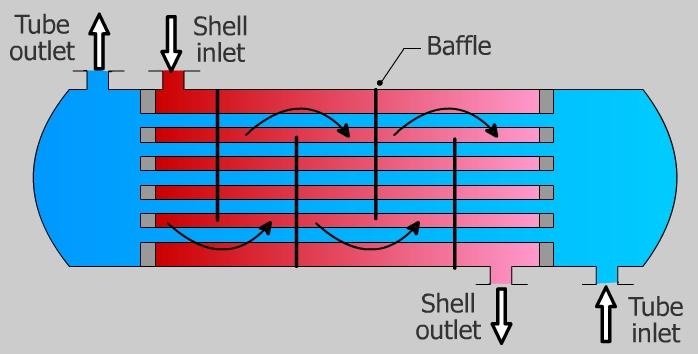

The design I'm interested in has the fire going though the pipes.

So it's the pipes that get exposed to the fire.

Basically the fire passes through the water. Not water pipes in the flame.

Life on a farm is a school of patience; you can't hurry the crops or make an ox in two days.

Henri Alain

Life on a farm is a school of patience; you can't hurry the crops or make an ox in two days.

Henri Alain

1

1

robin miller wrote:Thanks for the input.

The build-up of soot and scale is an issue.

This design DOES work.

Ive used it many times.

For the scale I'll need to seriously think about that one as it's bore water.

The pipes that carry the flame I used to clean with a metal pipe cleaner thing.

But down the road it may have had issues with the soott and creasote at the flue end.

So I'm thinking that an access panel would be needed.

As for the clean burn issue.

The exhaust gases were very clean.

Whoever built it got the dimensions correct.

It would use about a bucket of small sticks to fill a bath with hot water.

I'm starting to wonder if it's the only one in existence as I can't find any pics or info on the net. Yet.

Thanks

|

This is what a tiny ad looks like buck naked

The new kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|