Thanks in advance!

Thanks in advance!

![Filename: rocket1-(1).jpg

Description: [Thumbnail for rocket1-(1).jpg]](/t/17251/a/6012/rocket1-(1).jpg)

Lola Bachar wrote:

A conventional gas heater has his copper surrounded by water (very good conductor) wich is used to have more mass around the copper, so it wouldn't cool down that much. (and is used for the central heating system).

After 2 min of burning the stove and than running the water trough the tube, I generate steam and hot water for about 1 minute and than it cools down.

What I need is a good conductor around my tube, but that would go directly into the stove principals since it needs a very good insulator.

Seed the Mind, Harvest Ideas.

http://farmwhisperer.com

Bulk Herbs By The Pound

http://www.herbgrove.com

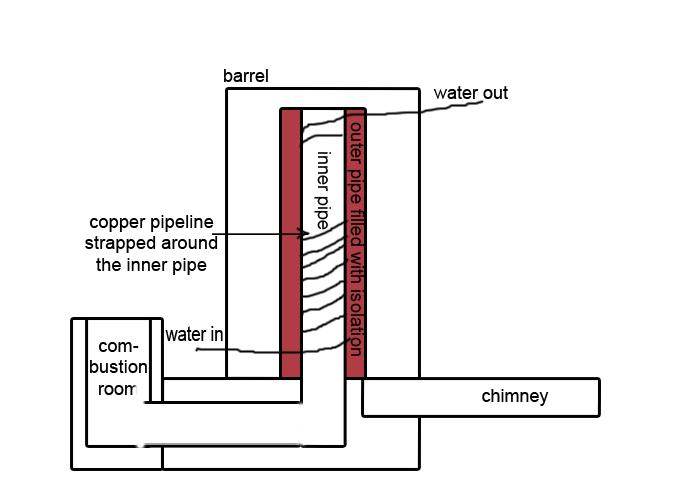

karol kerl wrote:You have to expose your 15m of copper pipeline directly to the heat, not strapp it around the inner pipe.

As you have it the heat can only be transfered, where the pipeline has direct contact to the inner pipe.

That's a pretty small contact area, even in the best case.

The by far largest surface part of your pipe is surrounded by insulation.

|

Slideshow boring ... losing consciousness ... just gonna take a quick nap on this tiny ad ...

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|