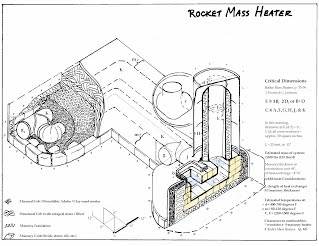

In our experience, the space between barrel and heat riser (H in the following diagram) can be substantially larger than the system CSA, but should not be smaller.

I suspect that the bigger it is, the more heat is radiated out from the barrel as opposed to going down into the bench. More stay time. If it's more than 4 times the system CSA, then the barrel is acting like a masonry-heater bell. We've seen this on some 6" heaters, and on Peter's batch boxes.

If it's more like 2-3 times CSA (a typical result using a brick heat riser), then it's acting more like the downdraft channels in a contraflow heater, and the exhaust gases are push-pulled downward by a combination of heat riser upward draft and exhaust chimney upward draft after the bench.

The diagram also shows the basic formula for heat riser height: at least 3x the height of the fuel feed, and at least 2x the length of the burn tunnel. So feed height : tunnel length : heat riser height would be 1 : 1.5 : 3+

For an 8" system, the brick channels that give the equivalent CSA are about 7" tall/deep by 7.5" wide, and the heights in inches are 16:24:48+. Depending on your bricks, the available space in the room, and your need for extra draft, a 50 or 52-inch heat riser is nice.

We do at least a 2" gap above the heat riser (keeping it within 1/4" of this dimension, half the radius, gives a very slight constriction that makes for a re-burn effect plus decent cooking temps in the top-center of the barrel).

And we try to do at least a 3" or 4" gap where the manifold enters the heat-exchange pipes, if it is coming straight out of the side of the barrel or a similar-sized manifold at a right angle.

This is an updated image of the same diagram from a different page on our website,

https://sites.google.com/a/ernieanderica.info/www/_/rsrc/1291441340872/rocketmassheaterpermitting/RocketHeater6in20000.jpg

Sorry about the missing "D" in the other one!

-Erica W