The past two years I have grown a small patch of "Cherokee Black Eagle" corn, which I got from Balk Lenoir. This is a very tall corn, I think one stalk reached 12 feet or more. I noticed that the stalks themselves are very sweet, almost like gnawing on sugar cane. This got me thinking that maybe I could use the corn stalks for syrup, like sugar cane or sorghum. So this year I tried the best I could with the equipment I have on hand. I read some blogs of folks down south home-processing sugar cane and adapted their ideas.

This is actually my second experiment in homegrown sweeteners, you can see my attempt at using mulberries here:

Will sun-dried mulberries work as a natural sweetener? Let's experiment.. The cornstalks show more promise.

My small milpa. With no corn left to harvest, I cut down these eight stalks. They were still green, but the pith was starting to get dry in some. I stripped off all the leaves, and used loppers to chop the stalks into short bits to fit in a pot.

Because I don't have any means of mechanically juicing these very tough stalks, I opted to simmer the stalks to hopefully dissolve out the sugars. Ended up using about 1.5 gallons of filtered water to just cover the stalks.

Simmered the stalks about two hours, then strained out the liquid into another pot to boil down. I did attempt to press more juice out of the stalks, but determined this needs much more heavy-duty equipment than I have on hand. So in the end, I just boiled down the simmering liquid.

Boiling down was a long process, and I am glad for my new range hood to vent all that steam! Eventually got it concentrated down enough to finish in a small sauce pan.

At this point, the liquid is sweet, but also tastes corny and has an almost salty mineral taste as well.

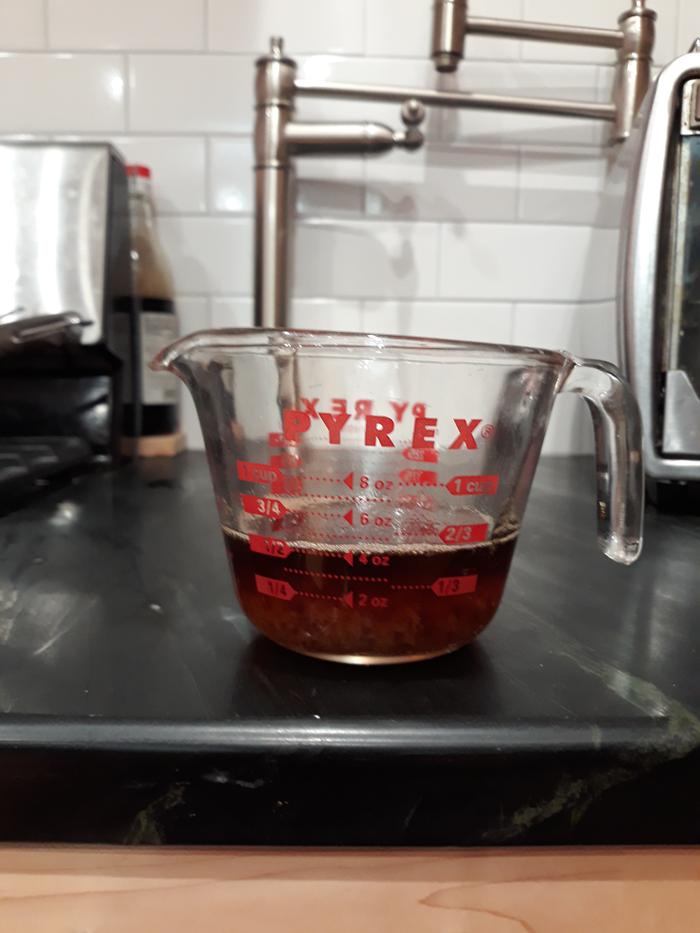

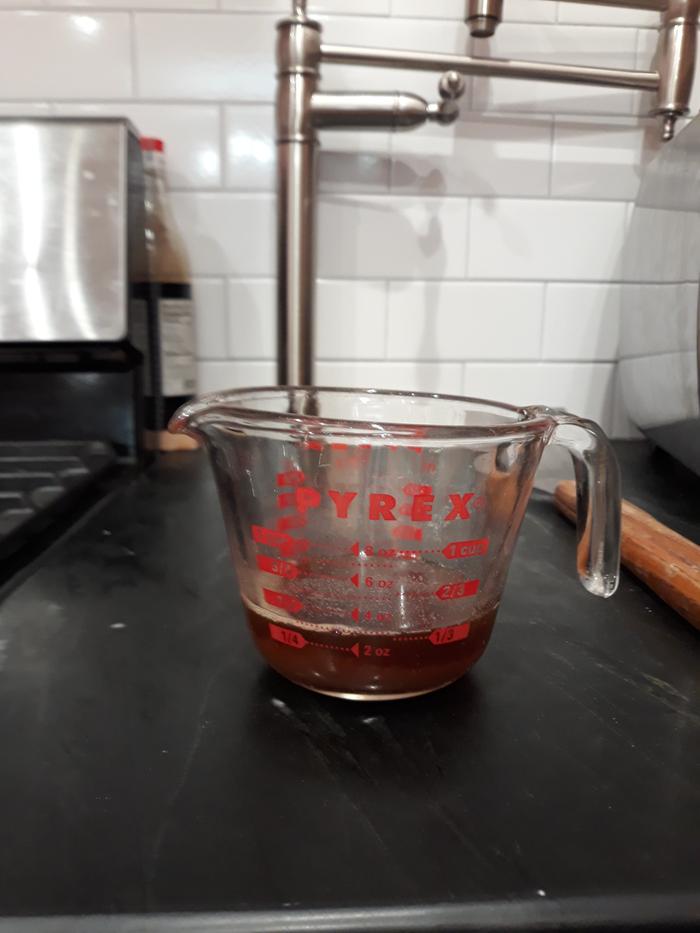

You can see it's a dark, clear syrup, with cloudy mineral precipitate at the bottom.

In the end, I got just about 1/3 cup of very dark, mineral-laced syrup from the 8 stalks of corn. It is sweet, but also strong tasting, like black-strap molasses. It was not a great product, but I think I see potential for improvement, and this could be a reasonable source of sweetener and a way to get food value out of what would otherwise just be compost.

To make a better syrup more efficiently I think I need to:

1. Strip off the outer part of cane. It's not adding to the sugar, it gives too strong a flavor, and it's just hardn and tough and makes everything more difficult. Specialized knives exist for stripping sugar cane, probably worth buying.

2. Actually juice the canes instead of just simmering. I could tell by taste that there was sugars left in the canes after simmering, but I couldn't make use of it. Also, the excess minerals may have precipitated out of the water. Again, there are specialized handmills for sugarcane. These cost close to $200 for quality mill, though, so probably not worth it for my scale. However, I might be able to borrow a cider press for free and use that to press stripped chunks of cane.

If life allows, I'll try some modifications next year.