Hi,

Thanks for the feedback Allen and Paul.

Great forum, lots of fascinating and inspirational stuff on here. I've been checking out some other threads and have seen some great ideas.

For the moment I am just interested in heating water for showers. I think a mass heater will come later. I have already built a prototype portable rocket stove powered pizza oven, turned out to be under powered with only a 4" heat riser, so back to the drawing board with that one.

My rocket stove water heater is going to be outdoor, mounted on a trailer for portability and using no electricity. This rules out the gas boiler heat exchanger Paul, as I dont think you would get a thermosiphon working through that much restriction and it would require a pump.

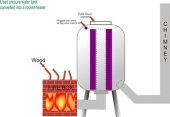

Here is a link to a rough sketch I made.

http://flockdraw.com/gallery/view/1780342

As you can see, the water in the heating side is open to the atmosphere, if it overheats it can expand into the feed tank or run

through the pressure release valve. This eliminates the chance of nasty, steamy explosions. As the water heats it rises up to the storage tank, where it moves through the heat exchanger coil, giving off heat and then returns to the burner to be reheated.

The water jacket in the boiler holds 19L, with the pipework and heat exchanger coil I would guess around about 24L of water in the heating circuit, with between 120L and 200L in the hot water storage tank (depending on what I can get my hands on).

I'm hoping to have a heat riser of about 36" high and as i dont think heat transfer is going to be anywhere near 100% i was going to oversize to 6" diameter.

I just have no idea how much heat I'll get out of it.

I realise it's not going to be the most efficient and after reading some other posts I'm not even sure if its a proper rocket stove as it doesnt use a cooling downdraught and perfect donut shaped whatyamacall it.

I' m pretty close to putting this thing together and I'd be really interested to hear your thoughts on safety and performance.

Thanks again.