1

1

Peter George wrote:Hi Steve: I'm a LONGtime Permies Lurker and I can't believe there's anyone else in South Bruce Peninsula besides myself that trolls Permies! I also can't believe Dale's from Wingham. In terms of sawdust, of course you can get cedar sawdust from a lot closer than Wingham--like Liverance's north of Ferndale, ON and in South Bruce Peninsula (Hayes). I have no earth bag experience, but lots of cordwood, some straw bale, and a good bit of plaster experience. Maybe I can be of some use before you're done, 'cause I'm local.

1

1

Dale Hodgins wrote:I would favor straw bale, cordwood, and standard stick frame from recycled materials, over any bag system.

Check out papercrete. Seems like you may be reinventing that.

positively optimistic 🙂 https://www.youtube.com/@613Builds

John McDoodle wrote:i've used perlite and concrete mixed - but it was in my rocket stove lol.

i stray from vermiculite because it absorbs moisture and has been reported to contain asbestos.

im also from (S.E) Ontario btw.

?

?

?

?

?

?

Christopher Steen wrote:

Steve: "My plaster is water proof, however, in order to avoid having to reapply waterproofing agents like wax over the plaster every year, A roof will protect it from rain and snow. Absolutely no bandaid roof paint or synthetic anythings on this one."

Christopher: " If your exterior plaster is 50:50 vermiculite:cement, well it is pretty rich but not gonna be waterproof as is with the vermiculite aggregates. 2 sand: 1 portland (ferrocement) is considered pretty waterproof when water content is .4 to portland, but cement will always be hydrophillic. What happens with freeze thaw cycles. Wax is like an exterior bandaid, it melts and wears off, while something like waterglass is like getting stitches; a great waterproofer that's breathable and permanent (by far my preference). Quality elastomerics and other coatings like graco are just bomber in the durability department, and although not breathable can be a component in a well designed wall system like the above stated example with interior earthen plaster with all those clay platelets moderating indoor humidity and wall assembly moisture. For someone in a wetter climate wanting a dome (or someone wanting to cover an exterior dome, vault, wall, slab) an appropriate and quality coating is no more a band aid than a second roof system in order to push a dome comfortably into a wetter freeze-thaw climate than where domes originally excelled. For example, a quality ferrocement vault work topped with waterglass or elastomeric like graco should last way longer than the highest quality galvanized metal quonset (let alone shingles) in the face of many different destructive forces. Portland cement is synthetic, just like that paint on the metal roof, asphalt shingles, and misprint rice bags. It's about how well something is used."

Steve Harvey wrote:

Hey folks, Steve here.

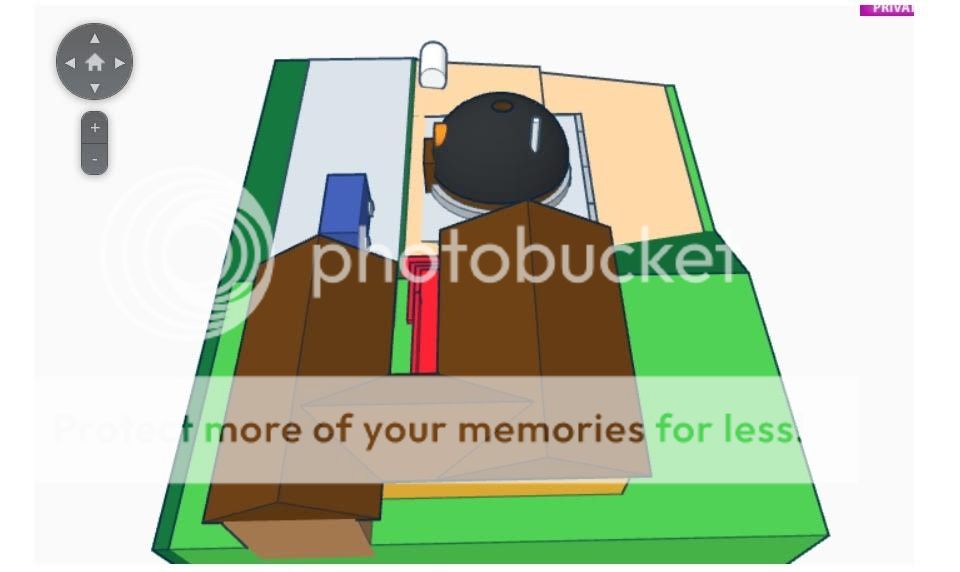

I am planning on building an earth bag house in Ontario. I would build this construction in place of an existing bunkie, on my brothers land. I was hoping to classify the earth bag house as an accessory building. According to the Ontario building code, a permit is not required for an accessory building less than 10m², or 108 ft².

In my case I am thinking - bathroom in one building (outhouse may be separate again) - cookhouse in another and a sleep house for sleep only... we'll see.

In my case I am thinking - bathroom in one building (outhouse may be separate again) - cookhouse in another and a sleep house for sleep only... we'll see.

Here are some steps I have been thinking of taking in order to carefully build this earth bag building.

3. I would then dig a 2ft deep trench around as the foundation of the earth bag house, and create a poured concrete foundation wall to start laying the bags behind.

6. I would also place many wooden cleats every 2 feet or so, in order to create a backing for roof panels, which would be contoured similar to the domed top of the earth house. If I create a cleat grid of 2ft² sections, I could then cut several 2ft² plywood boards to cover the whole upper portion of the dome, I would then shingle over the plywood roof. I hope you get the idea of this, I would also consider arranging the cleats in a geodesic arrangement. I am still working on drawing up a plan for this.

1

1

1

1

|

Some people look down on tiny ads, but this tiny ad thinks tiny ads are the sexiest ads

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|