What is the size of the port between the two chambers?

I would say whatever your fuel/air mixture ratio is, it looks great, how is it adjustable?

I noticed you did not brick the metal walls where the flame travels toward the twin stacks. Is the primary chamber floor...flat?

12 hours batch time with a 6" port,{wow} that is hard to believe, could you verify that practice/statistic please.

Is one batch approximately 1 heaping wheel barrow full of wood?

Is any type of ash tray installed yet? Is it easier to maintain ( is cold start-up fast/ is as ash removal or build-up a problem ) now with the much larger primary chamber configuration?

About adjusting your port size.., obviously the smaller the port... the longer the batch time, but I can also see the need for a large port if using green wood, or during cold start-up, would you agree?

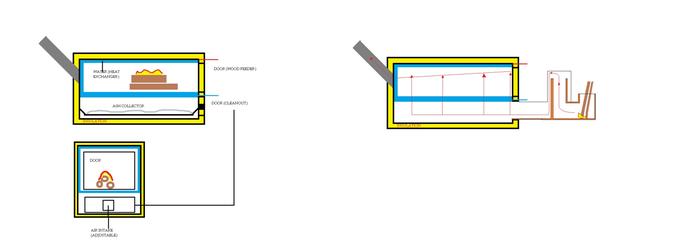

I can imagine a couple 1" pipe type auxiliary fuel ports/nozzles with your current set-up, located near the front secondary door, somewhat like I proposed in that latest previous diagram I submitted, and because your 'T" primary air supply is already near the front...might get increased flame length not only from the centralized triangle burn tunnel, but further blasting along those lower side walls that flow to the dual stacks. ~~~just a funny idea~~~

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

This does raise a couple of points, This is mostly outside my skill set but, the lowest temperature that gives you floors you are comfortable with, would seem to be best for

longevity of the system> I am not questioning whether the temperatures ~200dF~ are safe for 'PEX', merely longevity, this would be much higher than what 'Levittown'

floors were ever expected to 'run' at!

There are many totally mechanical mixing valves that need no energy input to provide a tempered water flow at small or very large volumes, they are a Set and forget

control that will give many years of service, if and when they give problems, it is usually related to 'hard water' and mineral deposits/scale !

I am hoping someone more familiar with 'PEX' and in floor heating will chime in here and report on ' best practices' operating temperatures and flows !

I would expect you might contemplate installing various 'in house' shut off valves useable in times of accident or maintenance. I know my kitchen water faucet has hot & cold supply line shut-off valves in the sink cabinet below the faucet, they rarely get used, but when they are used they are absolutely worth the installation. A suggest: never buy the cheapest shut-off valves that have a plastic valve stem!

So you have water tubing snaked around on the floor, embedded in a concrete like mass, or perhaps floor mounted radiators? Perhaps you could include a clear diagram/flow chart of the heating system, include various fixtures, valves, & function. It is difficult for me to imagine what your actual set-up is beyond the boiler itself which you have already explained fairly well. Did you ever find or install a mechanical thermostat valve & housing that is rated to work/bypass at the temperature you want? I think I remember you posting a few specifications beyond the boiler somewhere in this thread, or maybe at your website, but a diagram/flow chart should be easier to identify what your doing.

1

1

I hope that your Wife is recovering from her ordeal without any complications, which can so easily occur where there is a joint and movement

involved !

![Filename: Screenshot-from-2013-12-02-19-35-32.png

Description: [Thumbnail for Screenshot-from-2013-12-02-19-35-32.png]](/t/23295/a/12848/Screenshot-from-2013-12-02-19-35-32.png)

david willis wrote:I have always been afraid to use a used propane tank, because I am afraid it would blow up when I try to cut it, and they are kind of expensive.... I will have to think some more on that, but I do like the arch idea.

1

1

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

| I agree. Here's the link: http://stoves2.com |