projects blog http://thekulaproject.tumblr.com

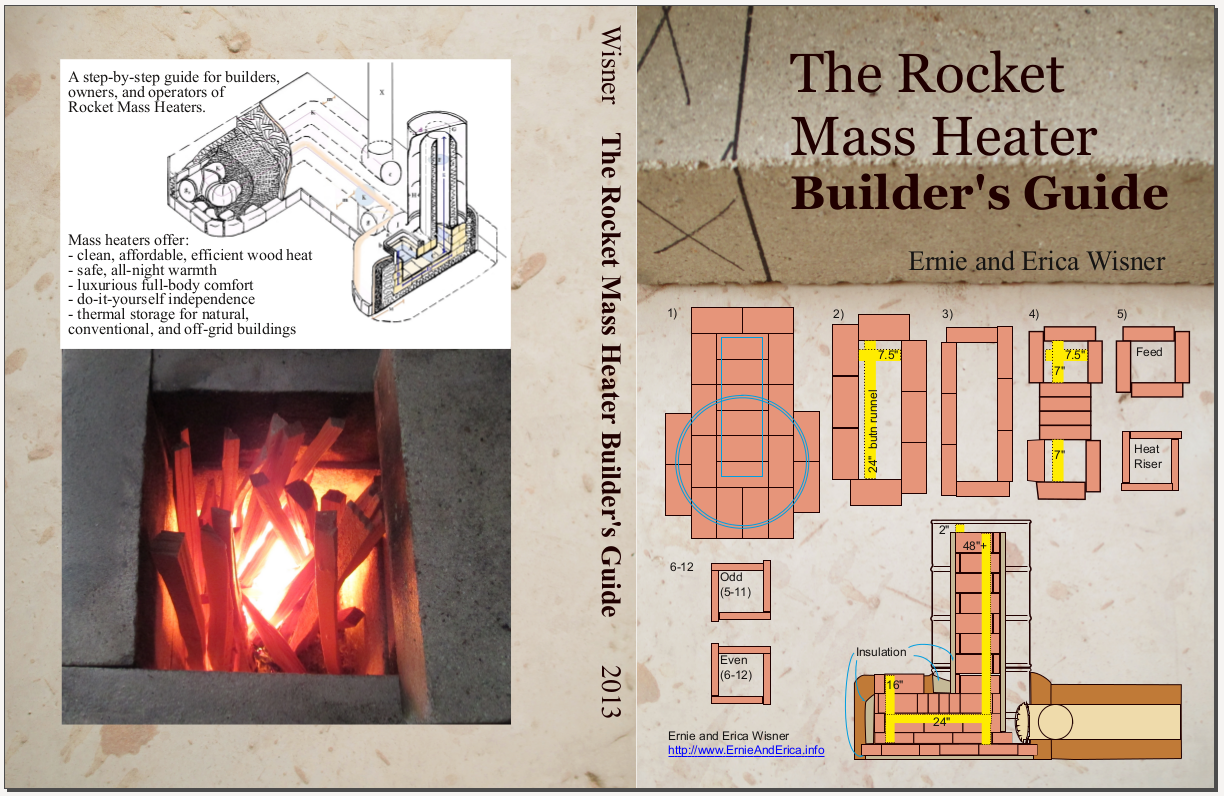

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

projects blog http://thekulaproject.tumblr.com

load al 19 short videos to 3/8ths of an entire E & E RMH build, any problems

load al 19 short videos to 3/8ths of an entire E & E RMH build, any problems

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

projects blog http://thekulaproject.tumblr.com

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Or what are they called in English? I switched to english mode on that site but they didn't seem to be linked. I will definitely see if those are an option here.

Or what are they called in English? I switched to english mode on that site but they didn't seem to be linked. I will definitely see if those are an option here.

projects blog http://thekulaproject.tumblr.com

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

projects blog http://thekulaproject.tumblr.com

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1

1

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

projects blog http://thekulaproject.tumblr.com

|

Chris has 3 apples and Monika has 4 apples. With this tiny ad they can finally make a pie!

Back the BEL - Invest in Permaculture

https://permies.com/w/bel-fundraiser

|