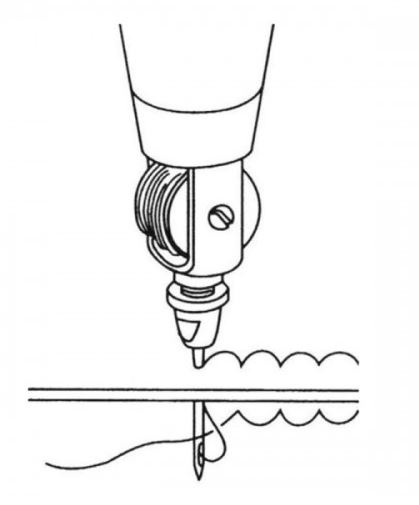

For the stitching around the lens cover, I was going to use a leather awl.

it works like this.

This is a great tool for fixing leather stitching and I've snatched up many a bargain at yard sales due to busted stitches. The owner takes the leather case to the local shoe or leather repair shop and they say it's going to cost fifty dollars or more to fix this stitches. So they put it in the yard sale free pile or quite often charge the crazy price of one whole dollar for the item. I take it home and spend 20 minutes with my awl and repair the stitches.

I don't know if you can see, but it looks like someone used this tool to repair the top of the camera case. The stitches are twice as long as the rest of the case and the thread four times as thick.

When I went to fix the stitching around the lens cover, I noticed that if I used the needle from this awl, it would tear the leather apart. It's far too big. But it's my only source of waxed thread and I'm far too lazy this week to wax my own. But what I can do is to cut a length of waxed string and unply it. The thread that comes with the awl (and fits in the handle of the awl for easy access), is made of two plys of two plied yarn. Which means it's a four-ply cable yarn - which is very strong and perfect for this kind of work. I'll cut a length of this and untwist it so that I have only one of the four strings. This looks like it exactly matches the original thread. After that, I'll find a strong enough needle and thimble to sew the leather.

I'll use a lock stitch because there's less bulk. Also, this part of the leather doesn't get much strain, so it should be strong enough to last another 70 years. If this was part of the case that had to support the weight of the camera (like a strap), then I would use the two needle method.

But before I start work, I'm going to moisten the outside of the leather, being careful to avoid getting any oil on the inside because I have a plan for fixing that tear that might involve glue.

2

2

4

4

2

2

2

2

2

2

2

2

1

1

2

2

3

3