For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

2

2

2

2

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

thomas rubino wrote:Yes Jody;Since it is creosote, then something is bad off.

Could be dimensions or as Phil suggested it could be your wood is not dry.

You should be getting hotter on top of the barrel. Because your not, then the temperature in the riser is not getting hot enough to consume the particulates.

That is the only way creosote can get past the riser.

If you can, get us some measurements. All of them. Depth of feed tube , length of burn tunnel roof, height of riser. Size of core (ie) 7.5 x 7.5 or 5.5 x 5.5)

What is your riser made off? Properly insulated ? What is your transition to horizontal area like ?

The 2" riser top gap, should have increased the barrel top temp, So changing it back rite now won't fix your problem. Later changing it to 3" or more is a good idea.

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

Length: The minimum burn tunnel

length is whatever is necessary to tunnel

under the bell. With a smaller barrel or cus-

tom bell, the burn tunnel could be shorter

without causing problems, but the bell must

never overhang above the feed.

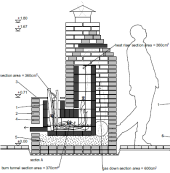

![Filename: Screen-Shot-2020-03-01-at-10.47.53-pm.gif

Description: I followed this patterrn in the book [Thumbnail for Screen-Shot-2020-03-01-at-10.47.53-pm.gif]](/t/135035/a/101376/Screen-Shot-2020-03-01-at-10.47.53-pm.gif)

3

3

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

1

1

![Filename: 4f18b320d1f95c5265a5c9ae876c38cc.jpg

Description: rocket scientists prematurely celebrating your successful rebuild! [Thumbnail for 4f18b320d1f95c5265a5c9ae876c38cc.jpg]](/t/135035/a/101580/4f18b320d1f95c5265a5c9ae876c38cc.jpg)

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

|

And that's when I woke up screaming. What does it mean tiny ad?

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|