posted 3 years ago

Hi Bob,

The CMU wall can support the floor joist in one of two ways. When the joists rest on top of the stem wall, the exterior joists are known as rim joists. That's what we do here when we're building above a crawl space and want to maximize headroom for the crawlspace (plumbers and electricians really appreciate that!). Then there's the approach we use when building above a full basement, and that's to hang the floor joists along the side of the stem wall so the top of the floor joists are even with the top of the mud sill.

The CASBA book drawings I mentioned don't give you prescriptive guidance like "use Simpson 2 x 12 joist hangers" or "use pressure treated 2 x 6 mudsills" , etc. because codes, best practice, and engineering requirements vary across the United States. In some places you might be able to use 2 x ledgers bolted to the stem wall to support the appropriately sized floor joists to carry the span and expected loads. Typically, there's a floor joist or blocking running underneath the interior edge of the straw bale wall. Both exterior and interior edges of the bale are elevated on a 2 x or 4 x (depends on engineering design) above the floor, and the space between the sills is filled with a rigid material that both drains and insulates.

Whichever method you go with, be sure to insulate the area behind the rim joist or the underside of the floor adjacent to the exterior wall. I know a lot of people avoid using rigid foam board if they can--definitely not my favorite building material either--but we use it for below-grade applications. Or you might consider some form of insulated concrete form block. There are several polystyrene ICFs available that, by themselves, reportedly give you an R-28 wall at 12" oe 13" thick (8" is concrete, 4" or 5" is foam). And there are two more natural options rated for below-grade applications. Out here in the west we have access to Faswall blocks, which are made from wood chips, and I believe there's a Canadian or East Coast distributor for Durisol, another wood chip block.

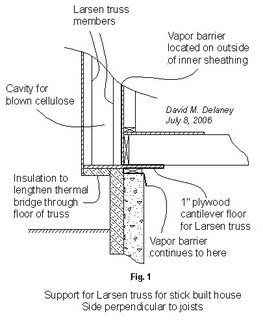

Finally, Chris Magwood at the Endeavor Centre in Ontario and Jacob Deva-Racusin at New FrameWorks in Vermont have adapted straw bale wall assemblies to increase the wall insulation and move the dew point out of the bales themselves. It's called a straw-cell wall. By themselves, the best R-value straw bales offer is with 3-string bales laid-flat. The bales themselves will be about 23" wide, and that'll get you to R-36 or so. In really cold places, it's not a bad idea to stack the bales against 2 x framing that has blown-in cellulose insulation, which bumps the R-value into the R-40s and 50s! There's a detail of a straw-cell wall in CASBA's book, and a very brief description. If you want to pursue that, you might give Chris or Jacob a shout. I have seen designs where the cellulose filled-wall is attached to the sill, and also where it's cantilevered over the foundation.

Jim

Many Hands Builders

2

2

1

1

1

1