Hello everyone,

it's my first post here, although I have been digging through the (rocket stove) forums for quite a bit.

I recently built my first "camping" rocket stove prototype out of steel tubing.

It is not working as I hoped it would… i.e. fast and hot fire and a rocket sound

Instead it is simmering and probably in the need for air.

I am looking for help to improve this

and would love to hear your inputs, as you probably already can see I did quite a few rookie mistakes

Please let me state in advance that:

+ yes, it's a metal construction without insulation (Metal is doomed, anyone?), so I can't expect the real rocket stove effects

I have used 80x80 mm steel tubing (a bit more than 3" x 3") with 4mm thick walls.

I went for the L design, with the rise:feed/airintake being a ratio of about 2:1, measuring 34cm and 17cm

The feed is also the air intake, with a metal bar approximately welded in the middle.

Please note that I do not have (yet) installed a grid, which would probably help with the air intake not being.

My main question is:

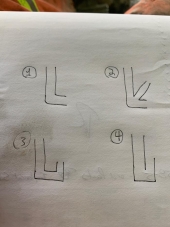

Do I change the current stove into a K design or a J design?

(see pictures of possible routes)

My primary goal would be: being able to boil water quickly and (considering the constraints of unisolated steel) efficiently, with a clean flame.

Fuel: Sticks and pellets.

The current ratio of riser and feed would allow for a recommended

J design ratio of 4:2:1 - turning the current feed into the burn chamber, and what I have read in here the J design seems to be "superior" at least for RMH (and I also love the great explanation from this site here

https://www.off-grid.rocks/rocket-stove-suderbyn.html which I used to determine my riser height according to material area) but I've read of so many people struggeling with this (smoke back etc.)

Also I am not sure how well this design would work with pellets (using a grid box for example) and maybe an adjustable opening at the bottom right of the feed tube for more air flow (and as a service door)

The

K design appears to be very popular (which does not mean it's good or efficient) and it feels like the "safer" road.

But here the fire burns higher up in the riser, which is also the burn chamber with heat going directly up… it already reads less efficient and like a not so clean burn, but what do I know.

Sorry for keeping it so theoretical, as you can clearly see I am having a hard time deciding which way to go for the best results with steel tubing only.

I'd love to simply build both and then compare, but time is scarce (maybe I should cut back the time I put into writing long threads

)

Anyone who read till here: Congrats, and thank you

Really looking forward to your inputs!

Best,

Max

1

1

)

)

)

)

1

1

1

1

2

2

1

1