8

8

A build too cool to miss:Mike's GreenhouseA great example:Joseph's Garden

All the soil info you'll ever need:

Redhawk's excellent soil-building series

11

11

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

10

10

thomas rubino wrote:Hi Trace;

Within reason, there is not much difference in how large the gap is.

The main idea is to provide safety without exhaust escaping into your building.

The other is to add mass.

The most common gap is 1/4" or so, the thickness of cardboard.

By using cardboard the mortar cannot bridge between the bells, the cardboard can be removed as you build or it can be left in place where it will char away.

Some folks will place copper heating coils between for water heating so they gap 1"-3" to allow room for the piping.

2

2

5

5

5

5

5

5

5

5

6

6

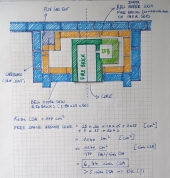

Julian Adam wrote:Because I am using 2 kinds of bricks, I would have a gap of 6 mm (1/4th inch) where the wider bricks are, and a gap of around 15 mm (0.6 inch) where the smaller bricks are. You are saying this will not make a noticeable difference in heat transfer, Scott and Thomas?

4

4

Scott Weinberg wrote:

I got behind on my replies, sorry.

Scott Weinberg wrote:

Julian, I presume the gap difference would happen because you want to keep the face of the bricks on the outside flush with each other? And rightly so, And I think Glen said it well, that things might not be quite as uniform, but... will you be able to really tell? That is always the question.

|

WARNING! Do not activate jet boots indoors or you will see a tiny ad:

3D Plans - Sauna Rocket Heater

https://permies.com/t/193729/Plans-Sauna-Rocket-Heater

|