10

10

8

8

10

10

5

5

9

9

7

7

8

8

9

9

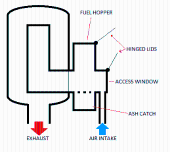

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

6

6

5

5

6

6

5

5

5

5

8

8

3

3

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

6

6

5

5

Nancy Reading wrote:Thanks for the update. It is logical that turbulence aids combustion, but you'd have thought more constriction wouldn't help - it's a bit of a contradiction isn't it?

Maybe a zircon paint might help give the metal some longevity?

5

5

Cristobal Cristo wrote:If the lifespan of the cheap 304 holder will be less than a month then it would make sens to try to fabricate it from RA330 high nickel alloy. They sell 4" pipes that could be drilled and topped with ceramic material. The topping could be also welded from RA330 sheet, but welding this material is quite demanding. However the pipes that they sell are thick walled, 4" would have the walls 6 mm thick so maybe it would affect the burn negatively.

4

4

6

6

7

7

4

4

Fox James wrote:Good luck with the new build, exciting for you and hopefully a Success!

PS good point with the ceramic fibre riser as that would be extremely unhealthy option!

If you even touch the stuff once super heated, it just produces so many air born particles!

7

7

3

3

| I agree. Here's the link: http://stoves2.com |