1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

Graham Chiu wrote:Has the Far North District Council required any particular documentation from you for this build?

2

2

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

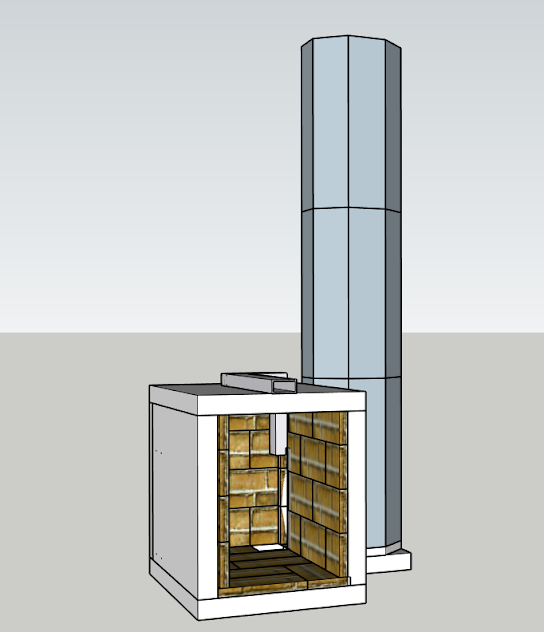

Nono Junang wrote:The second box of bricks is not a bell but rather a channel flowing like a snake (not straight) with opening going right / left / right.

I have made this to increase the path of the exhaust so that it gives even more energy to the bricks. The height of that channel is 1.7m.

Nono Junang wrote:I plan to cap the top of the first bell with a plate of stainless steel 1.5mm thick. I would also like to make a 200mmx200mm opening on that plate just on top of the heat riser and place a glass there. In addition I would like to have a mirror on the ceiling right on top of that glass so that I can have a view of what is happening inside the heat riser from the top.

regards, Peter

1

1

Nono Junang wrote:

Graham Chiu wrote:Has the Far North District Council required any particular documentation from you for this build?

Went there to talk about the system, but could not find someone who understands what I am planing to build. Best bet would have been to find an engineer that would stamp it, but then that would just drive the costs.

So I decided to build it and document each step, test and refine it to ensure that it meets the National Environmental Standards for Air Quality and then take care of the paper work later with all my test results and documentation.

The bricks are all mortared with lime mortar, so easy to dismantle and tweak.

Confirmation the appliance is approved for use under the National Environments Standards AS/NZS 4013, AS/NZ4012 - refer to the Ministry for the Environment.

Graham Chiu wrote:

Nono Junang wrote:

Graham Chiu wrote:Has the Far North District Council required any particular documentation from you for this build?

Went there to talk about the system, but could not find someone who understands what I am planing to build. Best bet would have been to find an engineer that would stamp it, but then that would just drive the costs.

So I decided to build it and document each step, test and refine it to ensure that it meets the National Environmental Standards for Air Quality and then take care of the paper work later with all my test results and documentation.

The bricks are all mortared with lime mortar, so easy to dismantle and tweak.

Well, I had a wood burner installed recently and this was from a major manufacturer. I had to do the building consent myself and it's a painful procedure even with all the manufacturer's documentation. You need to look at the consent forms to know what you have to be able to document, and I'd be surprised if the Council don't require that an engineer goes over your design, at your cost.

But in particular, you have this obstacle to overcome

Confirmation the appliance is approved for use under the National Environments Standards AS/NZS 4013, AS/NZ4012 - refer to the Ministry for the Environment.

https://www.fndc.govt.nz/services/building-consents-and-information/Guidance-Notes-for-building-in-the-Far-North/solid-fuel-appliances

I'm not sure how you propose to get your RMH approved for use. Better to find out now than later.

Nono Junang wrote:

I think it would be easier to approach council with a working system they can see rather than something on paper. And yes I know the pitfall with having to have everything certified by an engineer. We built a strawbale house and lots of our money unfortunately went into engineer fees. It is a pity that even for common sense stuff you have to go an see an engineer.

Peter van den Berg wrote:Think of 15 mm thick and possibly a cross welded underneath to make it more rigid.

Graham Chiu wrote:I may have a solution for you. If you configure your rocket mass heater with an oven, then you appear to be exempted from the clean air regulations. That is you don't need for your stove to be certified.

http://www.homewoodstoves.co.nz/stove-resources/environmental-standards-for-wood-burners

So I know of Matt Walker's stoves which are also used for heating. Of course you don't need to cook with it but the oven is an essential part. A cooking plate over a burn chamber is not considered a cooking stove.

Nono, i don't think the ppaint would resist for long at the top of the bell, inside!Nono Junang wrote:

Peter van den Berg wrote:Think of 15 mm thick and possibly a cross welded underneath to make it more rigid.

Hi Peter,

would it make sense to paint the underneath of the 15mm plate with heat resistant paint and/or some kind of rust protective paint?

Also would you protect the underneath of the steel plate with some ceramic fibre blanket (if so how thick) to minimize the heat shock? At least at the place directly above the heat riser? The plate is about 380mm above the heat riser.

Thanks!

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax Antone wrote:At what height will be the top of your bell?

Satamax Antone wrote:Because, besides cooking, a steel plate doesn't serve much purpose, except if you want to heat a room above. Two over dimensioned metal I beams, supporting firebrick slabs is easier to do. Or a poured single slab.

Nono Junang wrote:Hi Peter,

would it make sense to paint the underneath of the 15mm plate with heat resistant paint and/or some kind of rust protective paint?

Also would you protect the underneath of the steel plate with some ceramic fibre blanket (if so how thick) to minimize the heat shock? At least at the place directly above the heat riser? The plate is about 380mm above the heat riser.

regards, Peter

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Peter van den Berg wrote:

Nono Junang wrote:The second thought is doable and works, just one inch (25 mm) of superwool would be enough to take off the high heat. I am not sure this will prevent warping but since the 5 minutes riser is a lasting solution, shielding the top of the bell on the inside with superwool should be working. The only problem you are facing then is the need for a heat resistant adhesive to glue the superwool to the steel.

Hi Peter,

What do you think about using 25mm of ceramic fibre board instead of the steel plate and cross weld? I have used some for the bottom of the heat riser. They are rated 1260degC, come in 1000mmx500mm size and cost NZD30 and are also rigid enough to close the top of the bell. So since my opening is 1070mmx700mm, I would need max. 3 pieces glued together. I still have some leftover of ceramic board glue.

I wouldn't get much immediate heat release, but that would be ok. And that would be a lot cheaper and lighter than a steel plate.

1

1

Nono Junang wrote:What do you think about using 25mm of ceramic fibre board instead of the steel plate and cross weld? I have used some for the bottom of the heat riser. They are rated 1260degC, come in 1000mmx500mm size and cost NZD30 and are also rigid enough to close the top of the bell. So since my opening is 1070mmx700mm, I would need max. 3 pieces glued together. I still have some leftover of ceramic board glue.

I wouldn't get much immediate heat release, but that would be ok. And that would be a lot cheaper and lighter than a steel plate.

regards, Peter

Graham Chiu wrote:What temperatures are you recording at the top of your riser, and at the point where the top of the bell is?

regards, Peter

Graham Chiu wrote:What temperatures are you recording at the top of your riser, and at the point where the top of the bell is?

I see that Fox James is recording less than 600 deg C at the top of his riser ( not batch though ) even with ceramic blanket and so is able to use Neoceram glass https://permies.com/t/120/86886/Rocket-stove-hot-plate#797952

Peter van den Berg wrote:

Nono Junang wrote:What do you think about using 25mm of ceramic fibre board instead of the steel plate and cross weld? I have used some for the bottom of the heat riser. They are rated 1260degC, come in 1000mmx500mm size and cost NZD30 and are also rigid enough to close the top of the bell. So since my opening is 1070mmx700mm, I would need max. 3 pieces glued together. I still have some leftover of ceramic board glue.

I wouldn't get much immediate heat release, but that would be ok. And that would be a lot cheaper and lighter than a steel plate.

Yes, temperature-wise this would do the job. I don't have any experience with the ceramic board glue you mention. Of course you could try it and see whether it leaks and how to solve that. Is it possible to build your bell a little smaller so it can be done with just two boards?

Hmmm... Actually, it should be bigger instead because the top plate doesn't extract heat in this case.

1

1

1

1

Glenn Herbert wrote:In the US, masonry heater building code requires a double skin for pretty much the reason you are experiencing. Thermal expansion is obviously the culprit. Is the bell made of ordinary brick? Firebrick is recommended for at least the top half of a bell with the heat riser in it, because firebrick is formulated to not expand when heated (and to resist very high temperatures).

Adding refractory slabs or bricks inside the bell would probably completely solve the problem. An insulating blanket would be counterproductive.

Glenn Herbert wrote:I don't really have an opinion, other than making the slabs thick enough relative to their height and width that they will not be fragile to handle. You can tell best, being there with the material. I think 25mm would be adequate for heat tempering, though handling strength is an unknown for me.

Glenn Herbert wrote:I don't really have an opinion, other than making the slabs thick enough relative to their height and width that they will not be fragile to handle. You can tell best, being there with the material. I think 25mm would be adequate for heat tempering, though handling strength is an unknown for me.

regards, Peter

Peter van den Berg wrote:The construction as in the Mallorca build is used a dozen of times now and works well. Done in a number of different materials for the outer skin, raw stabilized bricks, mud bricks, normal building bricks, solid concrete bricks and hollow bricks filled with cob.

Anything above the riser in double skin with an expansion joint between the skins is what I would recommend. That said, a bit more won't hurt anybody.

The same construction is used in the Brussels build, see http://batchrocket.eu/en/applications#opensystems and scroll down to the second item.

Keep in mind that the top half of the bell will be slower to heat up and cool down this way as compared to the lower half.

The phenomenon of opening cracks on the outside during heating up is due to the inside of the bricks heating up too fast so the outside is lagging behind. Ultimately, those bricks could "walk apart" in time so the cracks won't close again when cooled off. Mark however, it's still quite normal to see a few hairline cracks in some places.

|

Whip out those weird instruments of science and probe away! I think it's a tiny ad:

Permaculture Design Magazine

https://permies.com/wiki/237407/permaculture/Permaculture-Design-Magazine

|