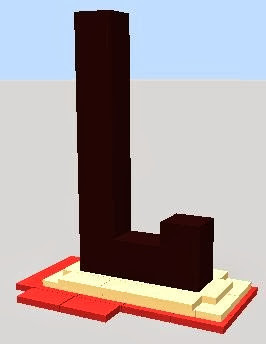

Rocket Mass Heater Plans: Annex 6" L-shaped Bench by Ernie and Erica

will be released to subscribers in:

soon!

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

The world needs Artisans like yourself to bring some joy into this world, let us just say that you are working in a new medium that feeds more than just the Soul.

and ecology, houses, energy and resoruces are a serious matter nowadays. I do love the way I'm walking now and I won't miss too much guitarmaking.

and ecology, houses, energy and resoruces are a serious matter nowadays. I do love the way I'm walking now and I won't miss too much guitarmaking.

It would be very helpful to know more about your location, summer and winter climate and altitude above sea level, I expect that it is mostly Mediterranean, and that you

need most of your heat in the morning, but that is merely a guess on my part !

I think that you would do well with a 6'' system, an 8'' is really for a place closer to 3-4 times your houses size !

I think that I understand that your interior walls are adobe, if so, then you can consider your Walls as being the all-ready built part of your Thermal Mass, on days when

you run your R.M.H. a lot you should have very warm backrests, your existing walls

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

1)You say that your Interior walls are Adobe, how thick in the middle of the wall, I am assuming that where 1 wall meets another, they get progressively thicker

with Rounded corners "so that the Devil has no Place to Hide "

What EXACTLY do you mean by Inner wooden beams ON (?) the Wall? If we are going to dodge beams/protect them from exposure, we will want to locate them precisely!

Is the space we are discussing based on Baraccata architecture. Can you go into more detail about the wall matrix of the structure?

Is there a way to post some photos of your structure on your "Picasa Page"? I would like to see inside each room, exterior view elevations shots, and location of planned RMH. What is the pitch of the roof? Is the roof insulated and by what? What is the circa date of the space

It is very important that we run our Hot exhaust Gases through a long enough horizontal chimney to extract the maximum amount of heat, HOWEVER it is just as important

to keep the number of elbows down to an absolute minimum !

If it is a rental, do you have "ad arbitrium" to modify structure with an RMH?

You are located South West of León, correct?

Jose Manuel Bonilla wrote:

... Guitars rules, but you can't live neither by them nor IN them.....

!

!

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Seriously, a local potter will be able to tell you about fire brick, Teach you all that you need to know about the clay slip that you are going to use like paint/glue to seal every

thing together, and make sure that the layer where you stopped working yesterday mates with todays Work ! This is also a good place to learn more about local clays !

Regardless of the type of brick that you use to dry stack and make up your test RMH, you will want to dip them in water and then into your clay slip, that and a little amount

of Cob, 5 -10 liters, certainly no more will seal all of the brick and heat passages before the barrel !

Late note ! Beautiful tile floors !

but it's a traditional work now somewhat difficult to find. I hope some day I'll be able to make my own cob house with earthen floor!

but it's a traditional work now somewhat difficult to find. I hope some day I'll be able to make my own cob house with earthen floor!

Your last sketch seems to show a slight pinching of the gap between the Heat Riser and the Barrel on the side closest to your vertical chimney and that would certainly be a

good idea, we do not want radiated heat from the barrel warming the chimney prior to its exiting though the roof!

Since we are talking about instrument builders I will add myself as another luthier, I have made 2 steel strings, a mountain dulcimer, a uke, an electric, and a 36 string lever harp that is for sale. Alan

Hello Alan!

Hello Alan!

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Manuel : I certainly would never under any circumstances ever do anything but have the Barrel NOT PINCHED on the side Directly above where the Transitional Area starts !

Did you understand about the part of needing reflective barriers with an air gap behind them, to keep your exposures cool...

...This combination will always work better then trying to wrap insulation around something you are trying to protect from too much heat ! A. L.

You will probably want to have reflective barriers with an air gap behind them mounted to the chimney, and to the wall directly between the Corridor / Hallway and your Work

Shop, possibly changing the door way into a wider arch as you live with your system a while !

...Ernies barrel and a half works best with a certain type of 55 gal barrel Fairly easily findable over here. I have only learned his way to do the 1.5 barrel arrangement, and I don't have a clue how he has explained how to do it with regular barrels !

My kind of barrel comes with one end open, closed with a full sized lid held in place with a clamping band so that you can reseal it. When you have at least one end of an open

barrel to mate with the carefully trimmed end of a matching Barrel The cut end just mates with the open ended second barrel and can be reclaimed to lock them together, a

thin ribbon type gasket will sometimes be used to create additional surface area that the clamp bears down on, but the two sections will be protected by and sealed with Cob!

The lower barrel section does support the weight of the upper barrel, this gives you a chance to pack additional insulation, Perlite, Vermiculite the lighter weights of Pumice /

/Tuff (sp) around that section of the bottom 1/2 barrel. Be generous about saving a large area for the Funnel that First moves the gases horizontally through the transitional

area!

Ernie should have explained this part

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

We have still one more friend looking in on your project from her abode on the Canary Islands, and everything that comes into there must be specially

ordered, not like here in the States where we 'know the price of everything and the value of nothing' ! She is working in on using her floor to run her horizontal piping through

to make her thermal mass, her project has drifted on for almost 2 years with some breaks to gather materials, and especially to persuade local craftsmen to attempt to do it

her way !

If you do have an opertunity to get two identical Barrels with clamping ends, Then I THINK that you should make it a priority to get two of them that are identical As

Soon As Possible.

You do understand about burning off the paint on the outside of the barrels prior to doing your test fire out-of-doors ?

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Thank you I learned something, I talked to my friend who did at the metal cuts for the R.M.H. we built with Ernie and Erica Wisner, My friend Miles reports that the two

barrels were trimmed leayeing their barrel end flanges intact, and that Ernie gently pounded on the clamping band to slightly flatten it to distribute the clamping forces over the

flanged ends of both barrels, I expect that that is what your instructions from Ernie and Erica Wisner told you to do !

¡Hola Manuel desde La Palma!

Well, not 2 years Al, only 1! I am still more into waterproofing and planning windows than into heating...

Manuel, you are doing fine, I could not even burn the paint properly and will go for an iron cylinder. Don't have those barrels here, they do not open, they are from REPSOL. Their painted name resisted a whole day burning jaja!

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

I assume that you are going the insulate the outside of your 1/2 bricks and cap it with Cob in a Arch or arc

possibly adding a flying Buttress element for structural strength, like on the sides of Early Churches.

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

If you can't pinch towards the interior vertical chimney, and you don't want any pinch directly over your transitional area leading towards your work room,

than you must protect those exposures, I Think that a highly reflective J shaped ( the curve of the 'J' directly around and behind the barrel, and the

long side finishing up at your work rooms door should protect the chimney and the corridor/work room wall with about 5-8 cm air space behind the J shaped

Reflector

In my mind I have an Image of a rather large curved mirror of stainless steel , its mirrored surface would make the newly more confined area of the Corridor

/hallway 'look a little more roomy' !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

I hope it will be fixed soon so I could go again to buy the flues and the rest of the stuff.

I hope it will be fixed soon so I could go again to buy the flues and the rest of the stuff.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

to 16) - 8 layers sideways for the riser.

to 16) - 8 layers sideways for the riser.

Are the same bricks that I saw set up new to the blue barrel the same ones you had on your picasso File !

Speaking of that great man, color me plaid,

i be confused

Here I only make a suggestion for you to decide what you want to do, you could have a full thickness fire brick to absorb the blows and jars directly under the feed tube,

Thicker bricks for the burn floor, easy to change.

Thicker bricks for the burn floor, easy to change.

I need you to look up a running bond under brick laying, your sketch up does not show it as part of your plans and the ' running bond ' will make for a stronger build, even

dry stacking.

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

A running bond in bricks is where after you finish a course/level of bricks, instead of laying one brick directly on top of the next you off set the next layer,usually by 1/2 of the

length of the brick ! This means there are no two layers of bricks that have there ends lined up one on top of the other, a good running bonds both simple and strong !

The sketch up system that you were using did not show the stagger of the bricks, the stagger or offset you have on your bricks is fine! together and repeated they make

a running bond.

I have no idea how 'good' the bricks you have are, I have never seen anything like them ! You will have to ask the person who sold them to you how suitable they

are !

Do you have a list of questions for the potteress !?

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

You want your insulation to have nice flowing lines, and allow the C S & P

time to slump a little, and then firm up, sharp right angles are where you can get cracks

the straight right angles in the sketch could cause confusion and problems

Do you have a list of questions for the potteress !?

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

because of the Crap content videos to be found there, like 10 videos showing people trying to make RMHs out of ALL STEEL , next month there will be 100 people

posting pictures of crap ALL STEEL Stoves of flaming death !! Please pass on to our new friends the Permies.com and our sister site richsoil.com, with a

Warning about crap on You Tube

hope that translates clearly ! Big AL

hope that translates clearly ! Big ALSuccess has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

hope that translates clearly !

Please, there's one question never answered to me abut the test-run:

Regardless of the type of brick that you use to dry stack and make up your test RMH, you will want to dip them in water and then into your clay slip, that and a little amount

of Cob, 5 -10 liters, certainly no more will seal all of the brick and heat passages before the barrel !

With my duct work as tightly sealed as possible and a layer of clay slip to show any cracks, I would try my RMH without the barrel, then when I hear the dragons friendly deep

throated roar, I would hook up all my horizontal ductwork, and about 2 meters of vertical chimney and try that, only if this gives me problems would I consider unhooking the

horizontal piping and going straight to an elbow and the vertical pipe!

This last test would only be necessary if your rocket with the barrel on did not draw as well as before, and is the best way on determining if the problem (which we

already have proved is not in the brick work section) is in the RMH from the barrel out through the transitional zone to the horizontal pipe, because we have eliminated ALL of

the horizontal pipe from the test !

|

It's just like a fortune cookie, but instead of a cookie, it's pie. And we'll call it ... tiny ad:

PIE - The Easy Way to Support Permies.com

https://permies.com/t/240094/PIE-Easy-Support-Permies

|